Equatorial Guinea H/B Series High-power Reducer

Category:

Product Description

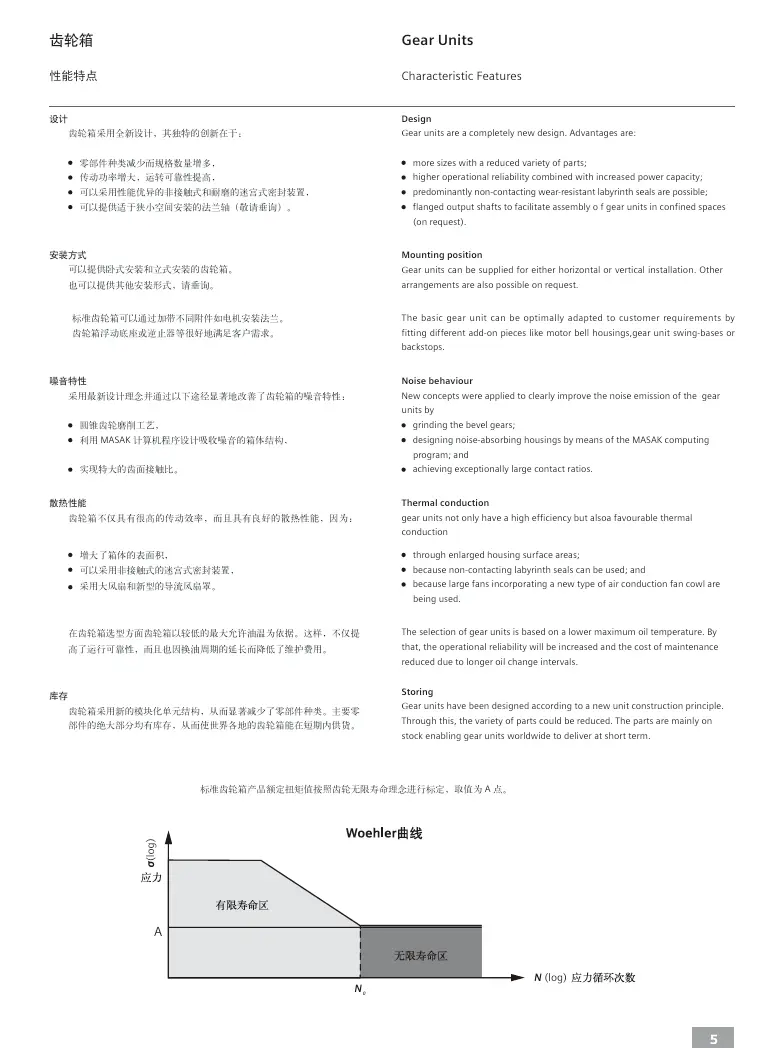

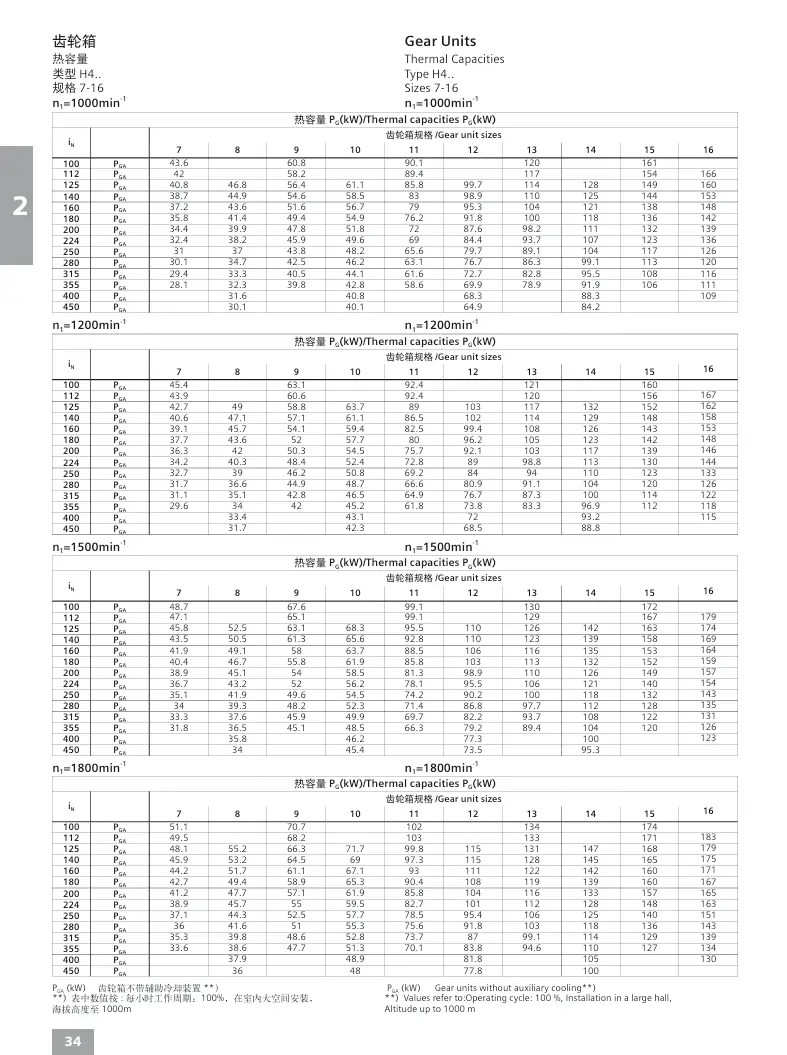

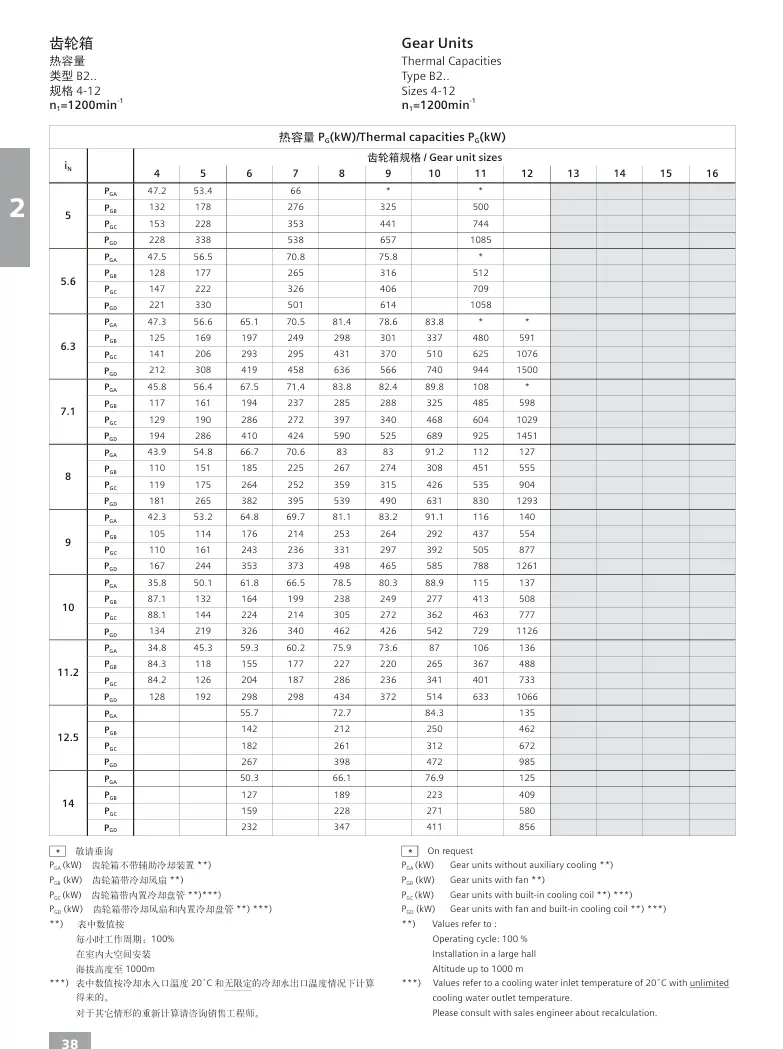

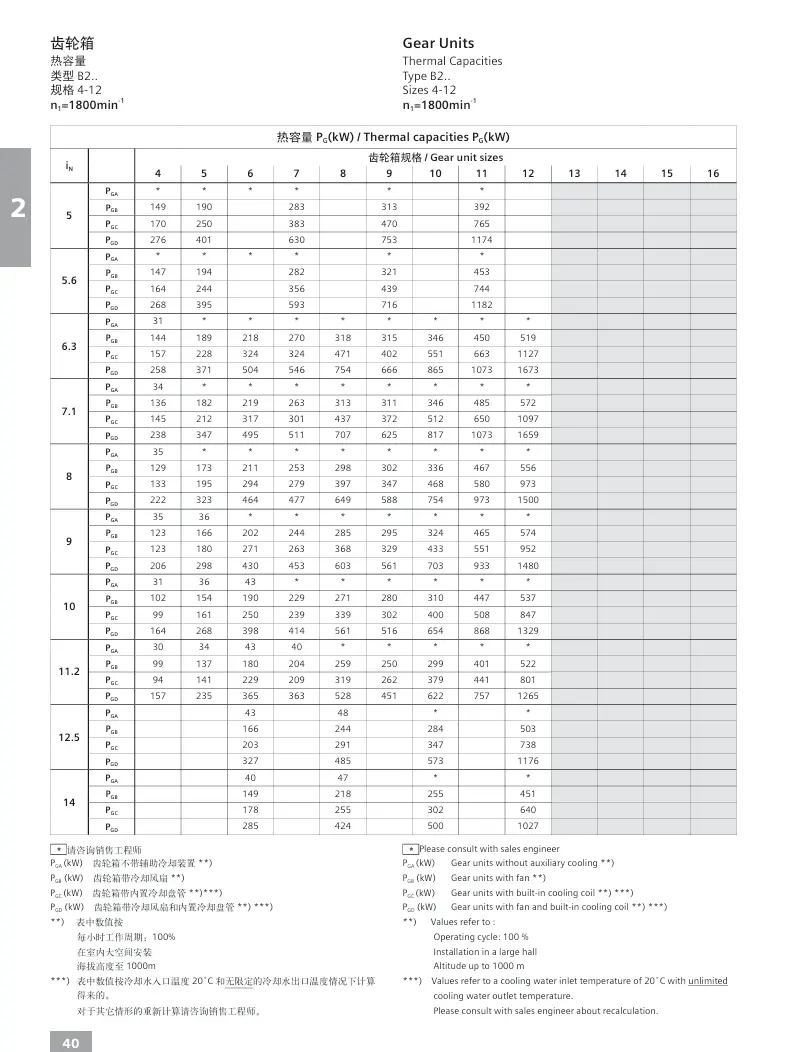

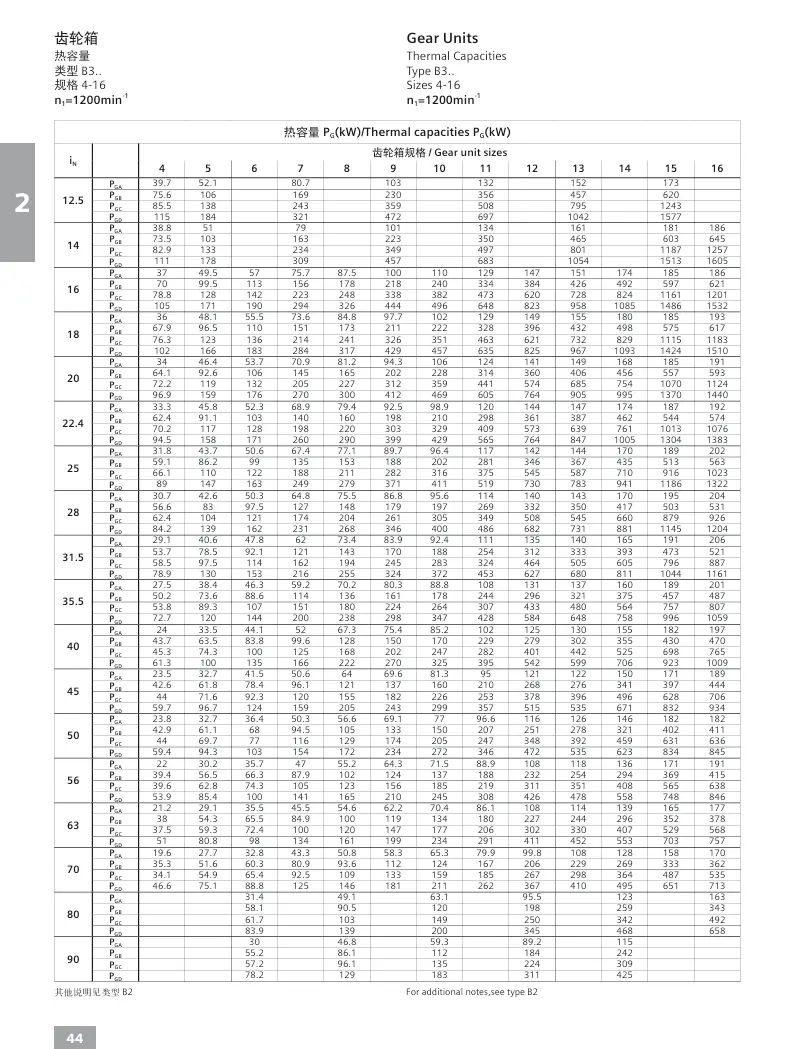

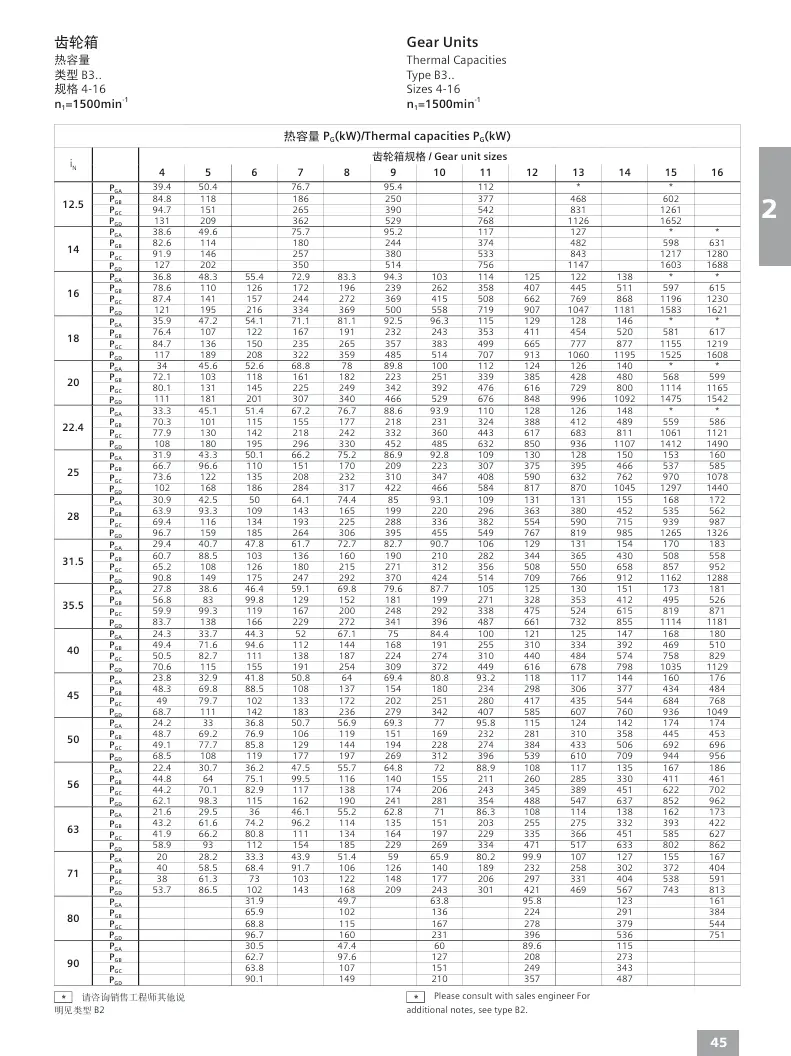

HB standard industrial gearboxes adopt sound-absorbing box structure, large box surface area and large fans, cylindrical gears and spiral bevel gears all adopt advanced gear grinding technology, so that the temperature rise and noise of the whole machine are reduced, the reliability of operation is improved, and the transmission power is increased.

Product features of precision planetary reducer:

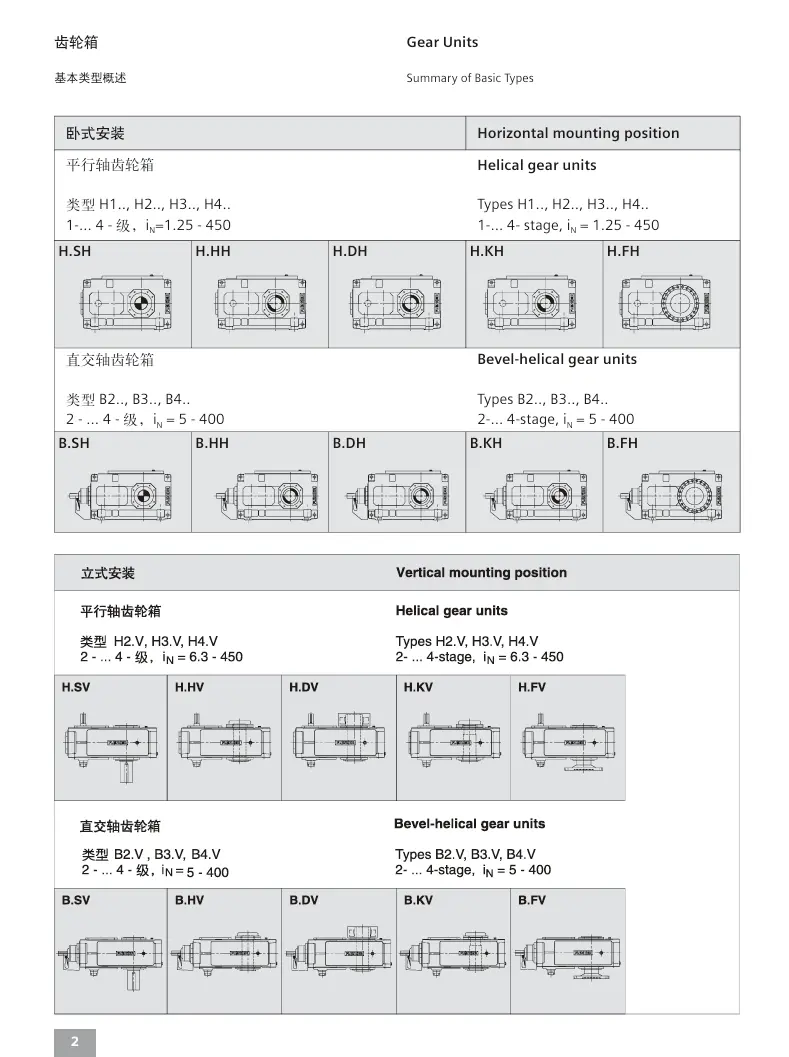

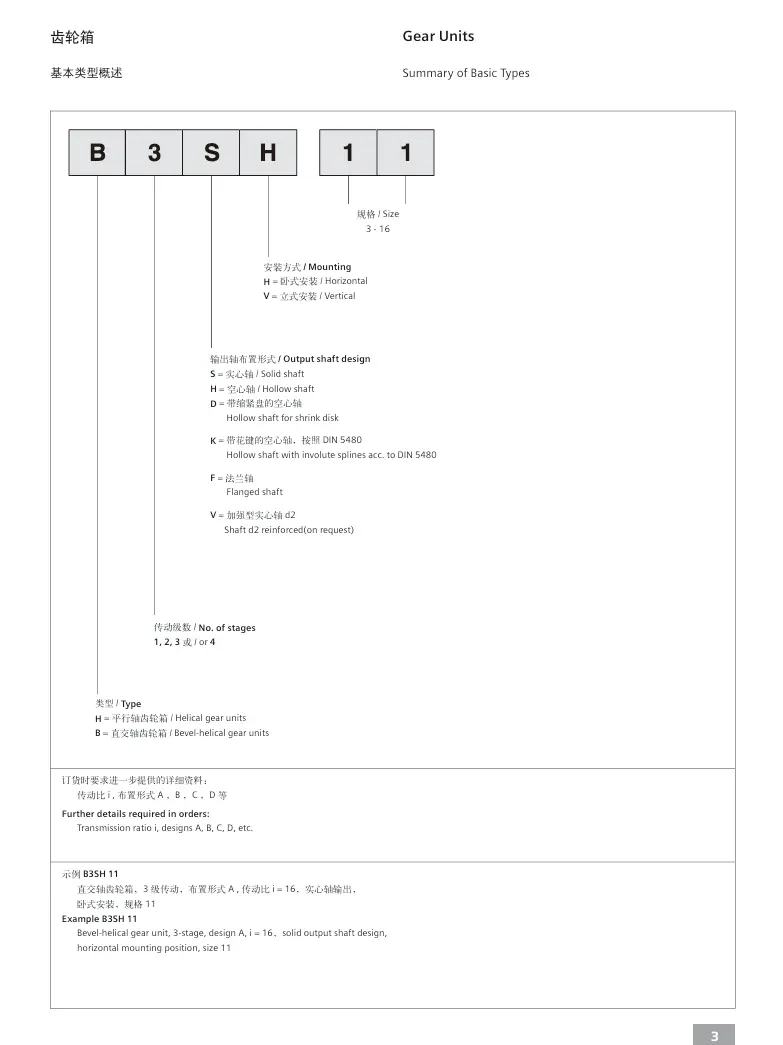

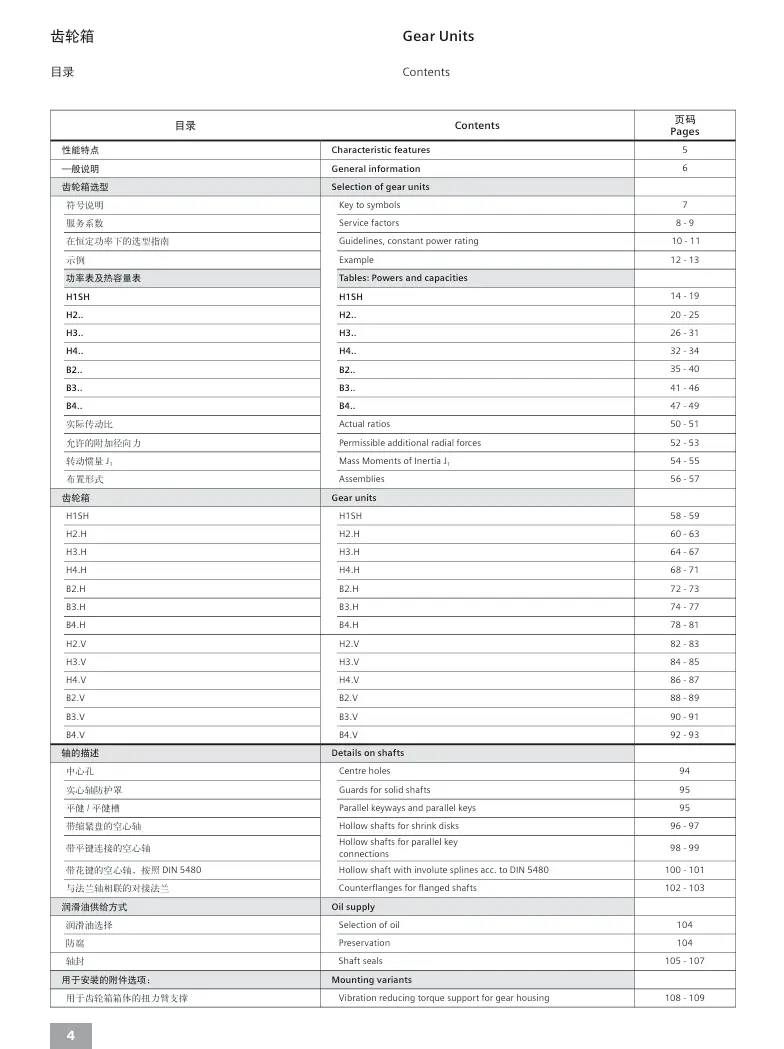

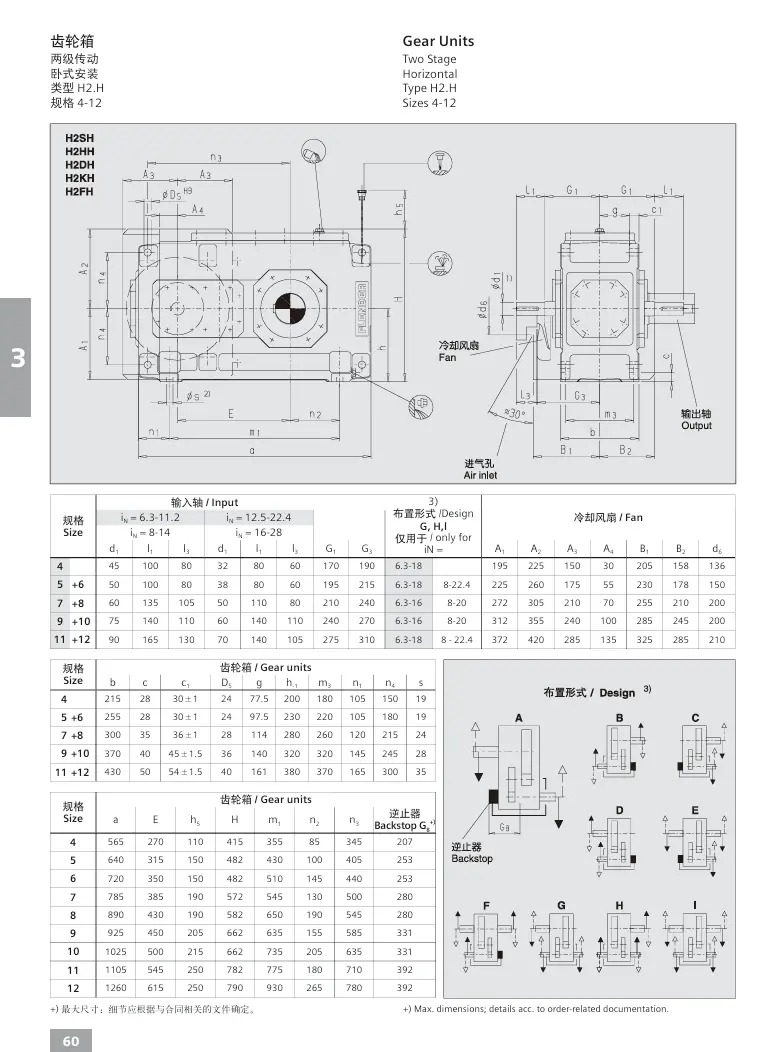

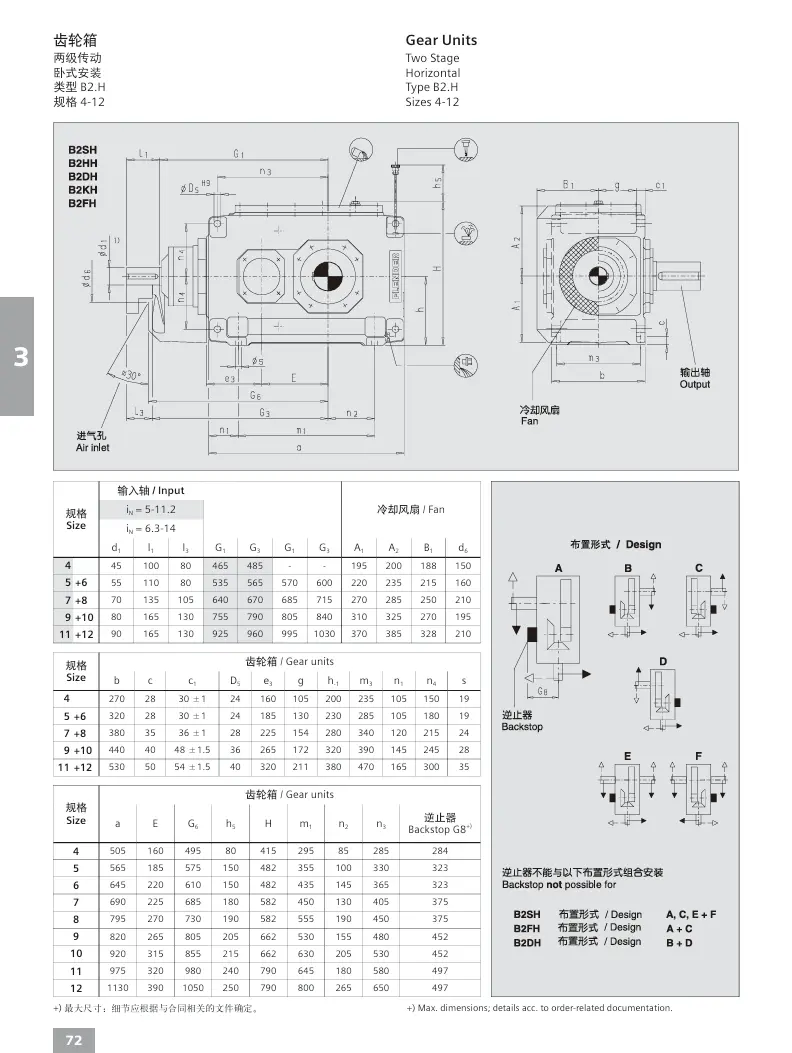

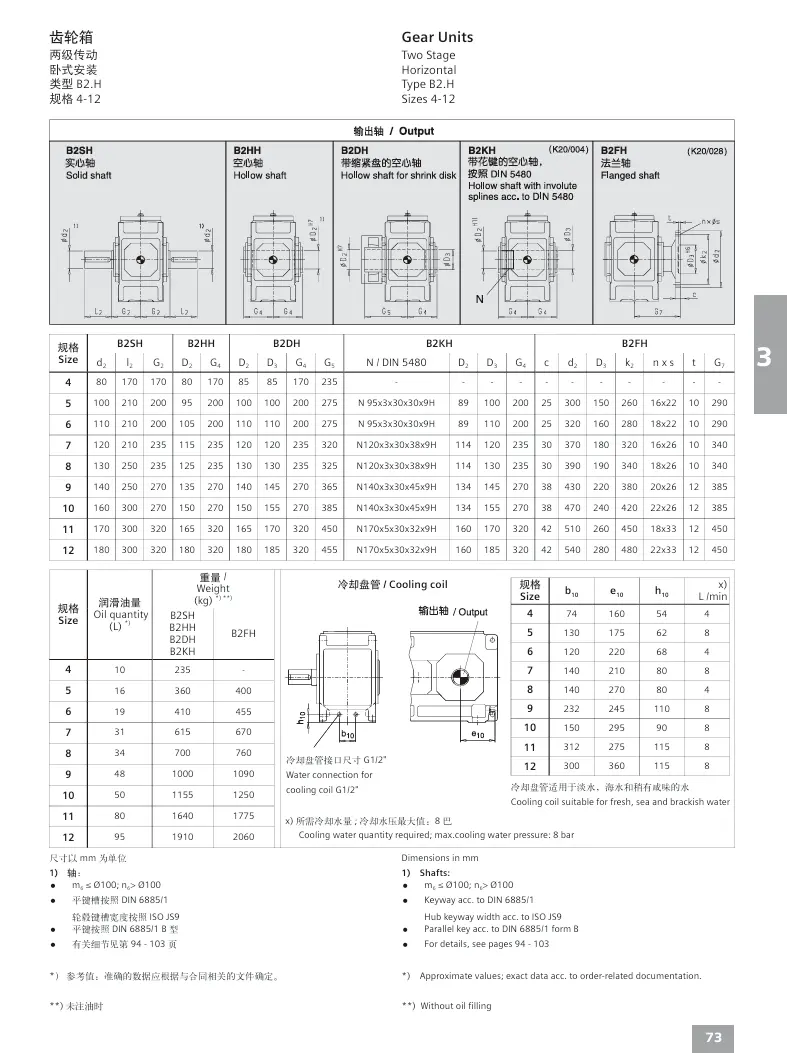

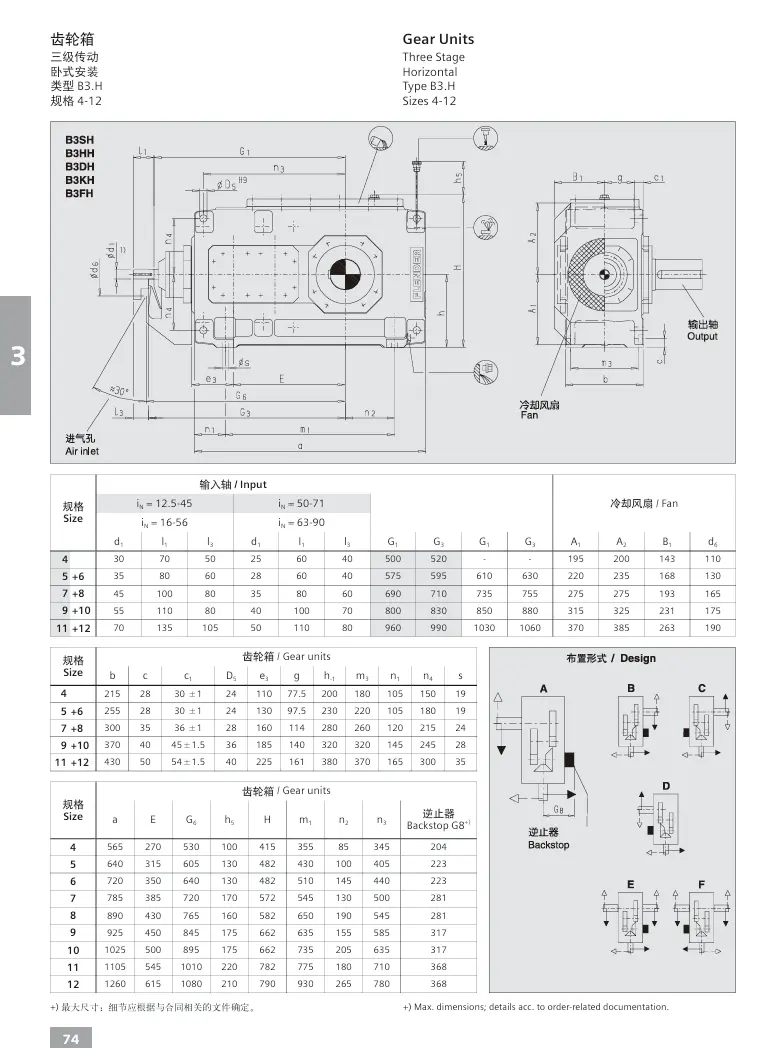

1. Industrial gearboxes adopt a universal design scheme to realize a universal box for parallel shafts and straight-cross shafts, with fewer types of parts and more specifications and models.

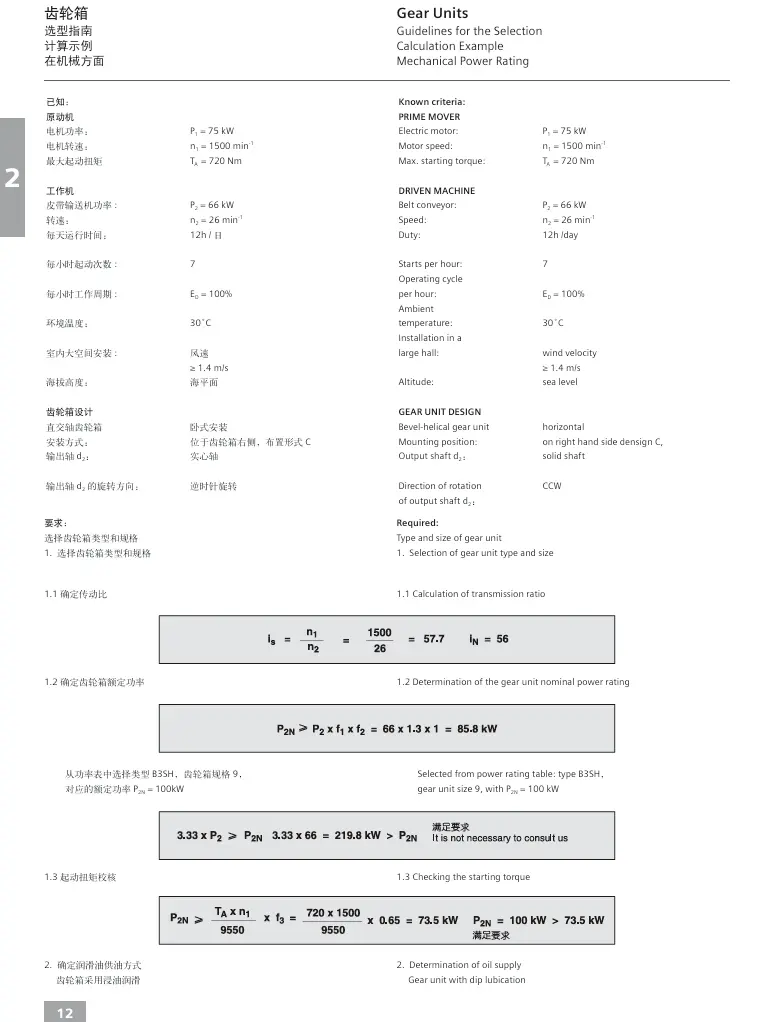

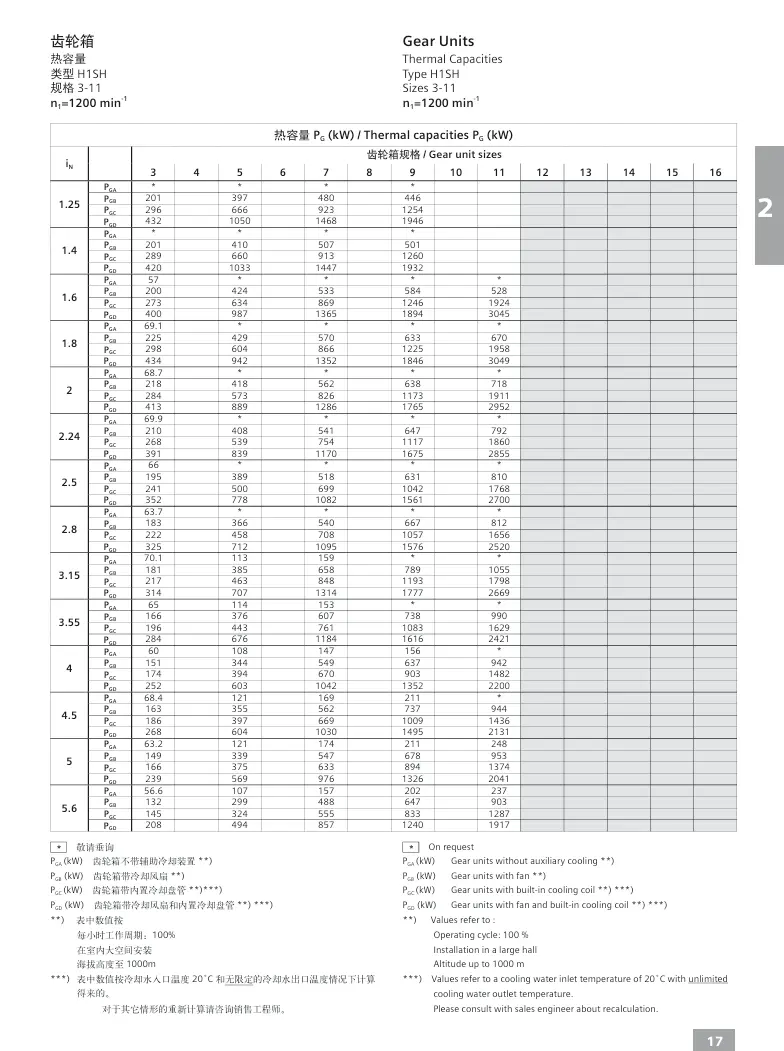

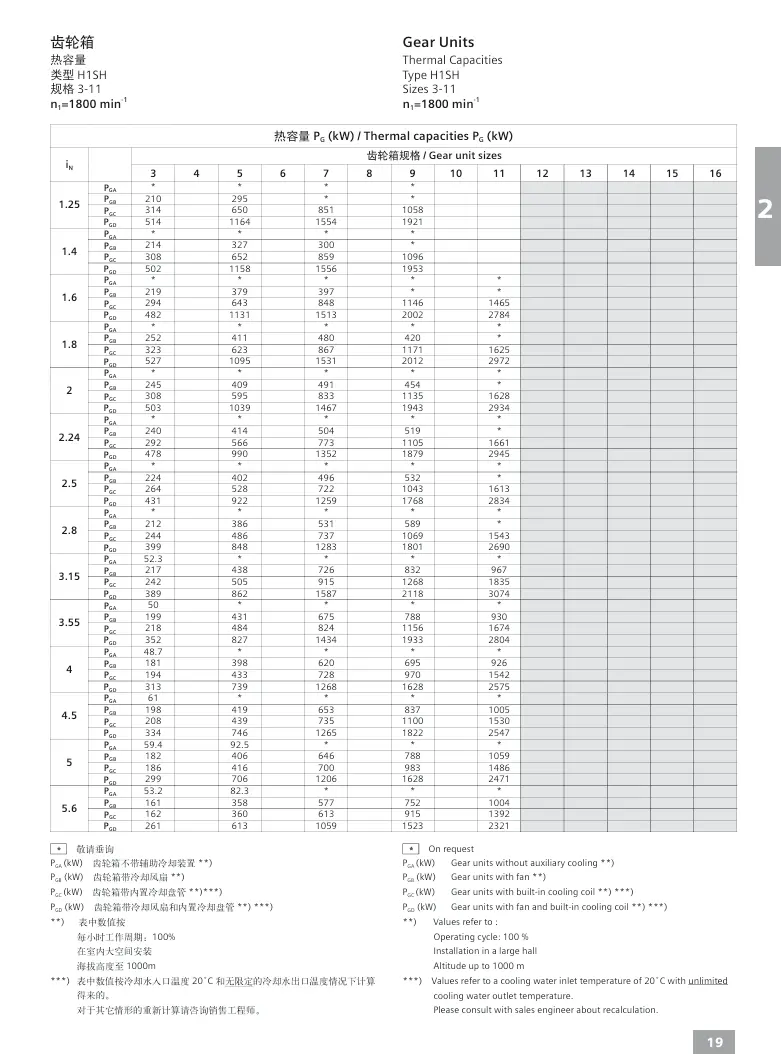

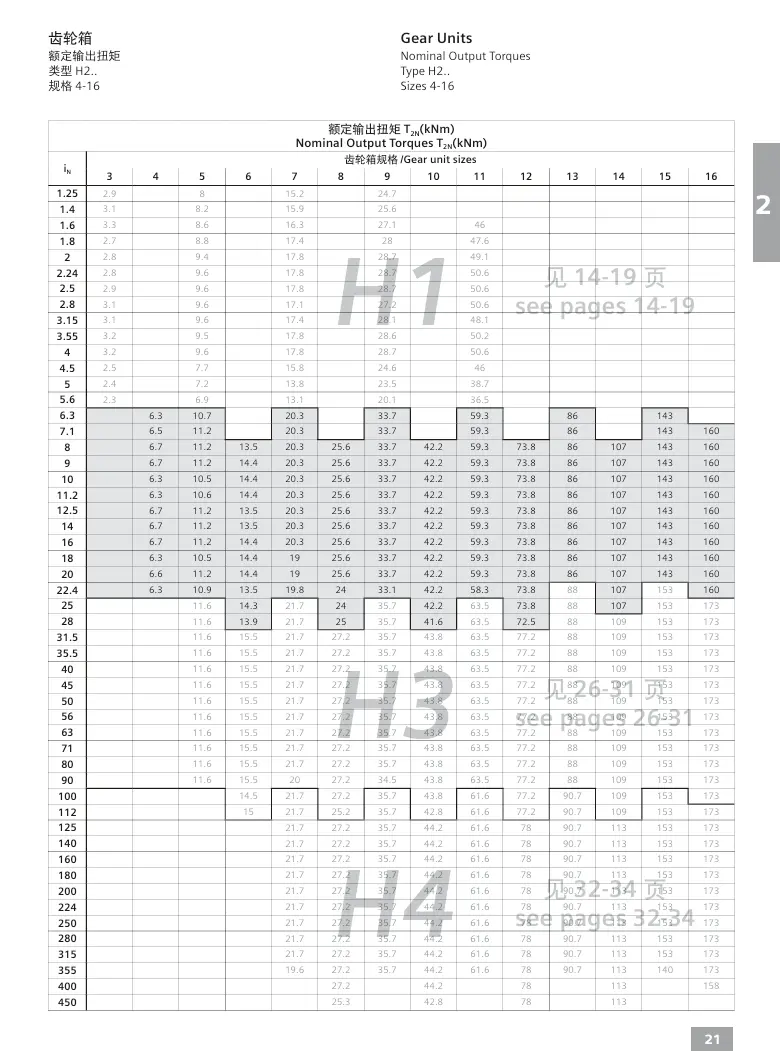

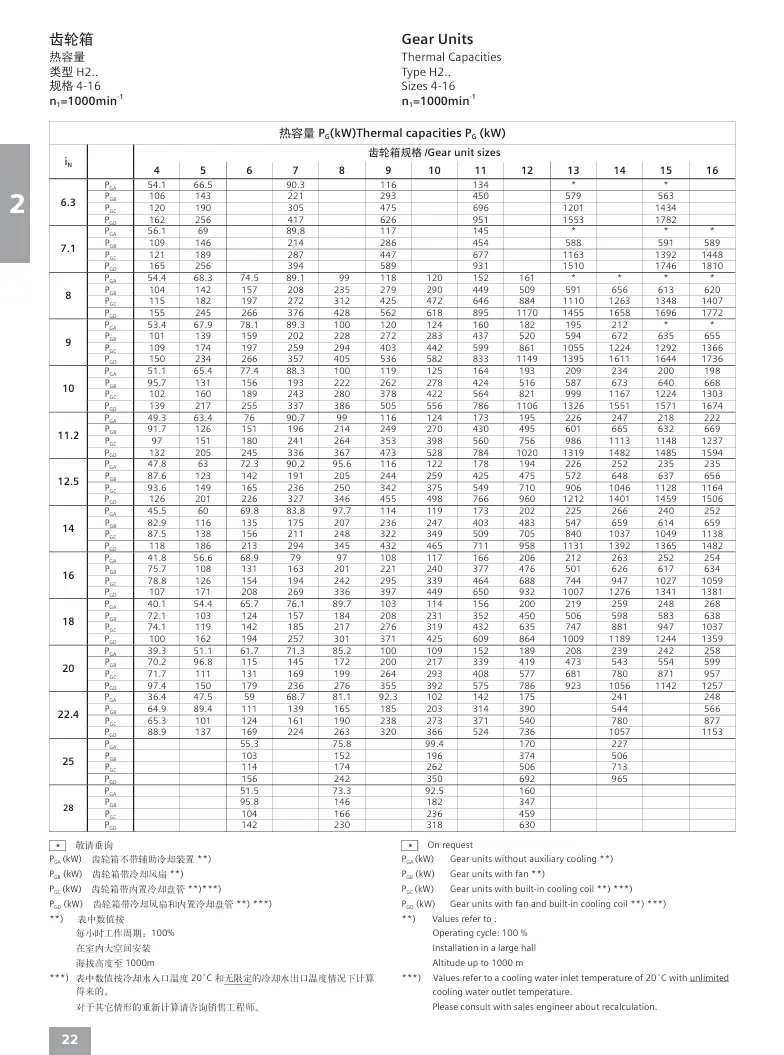

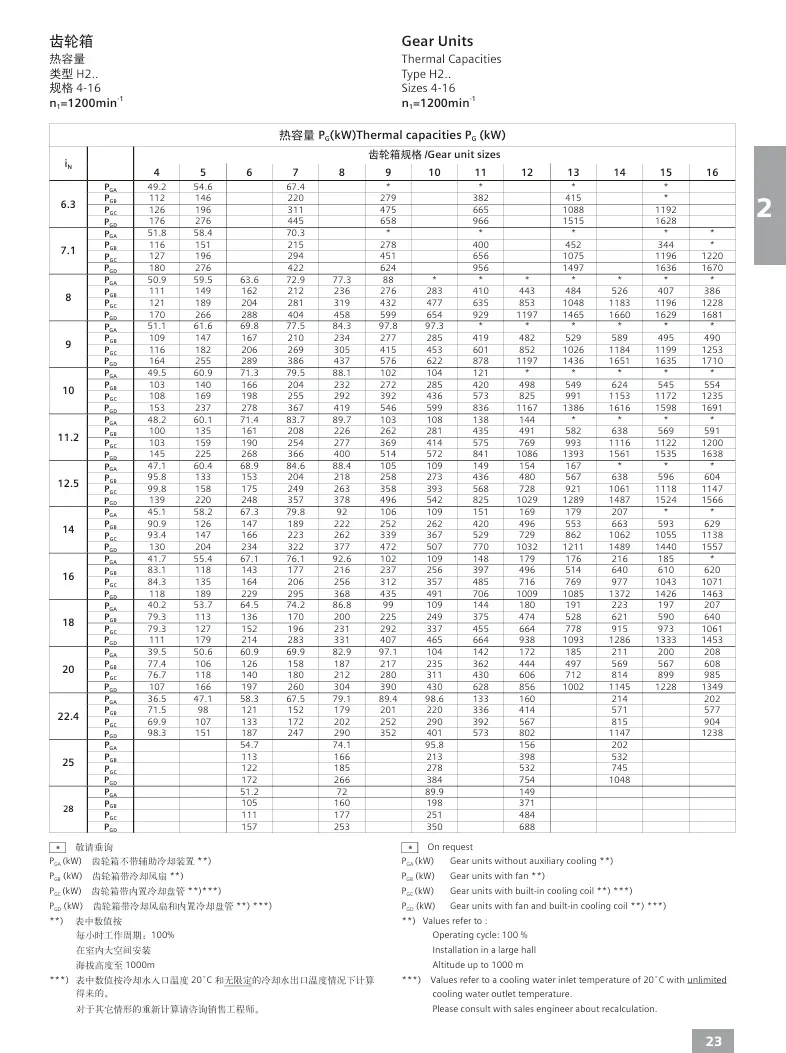

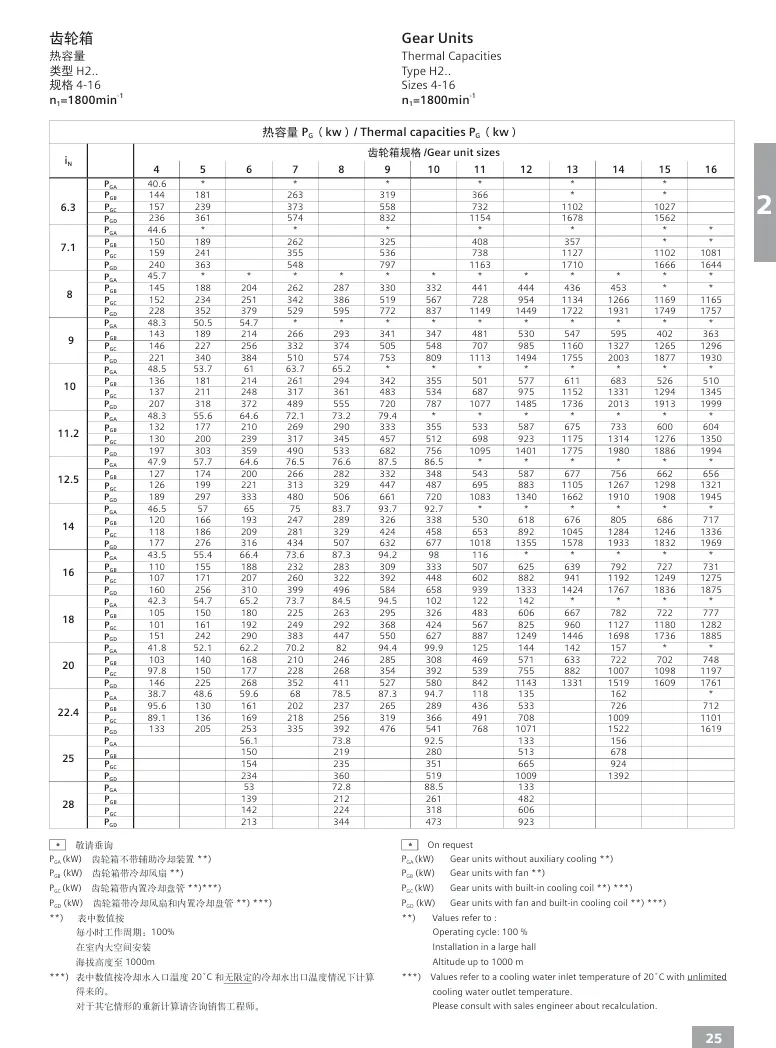

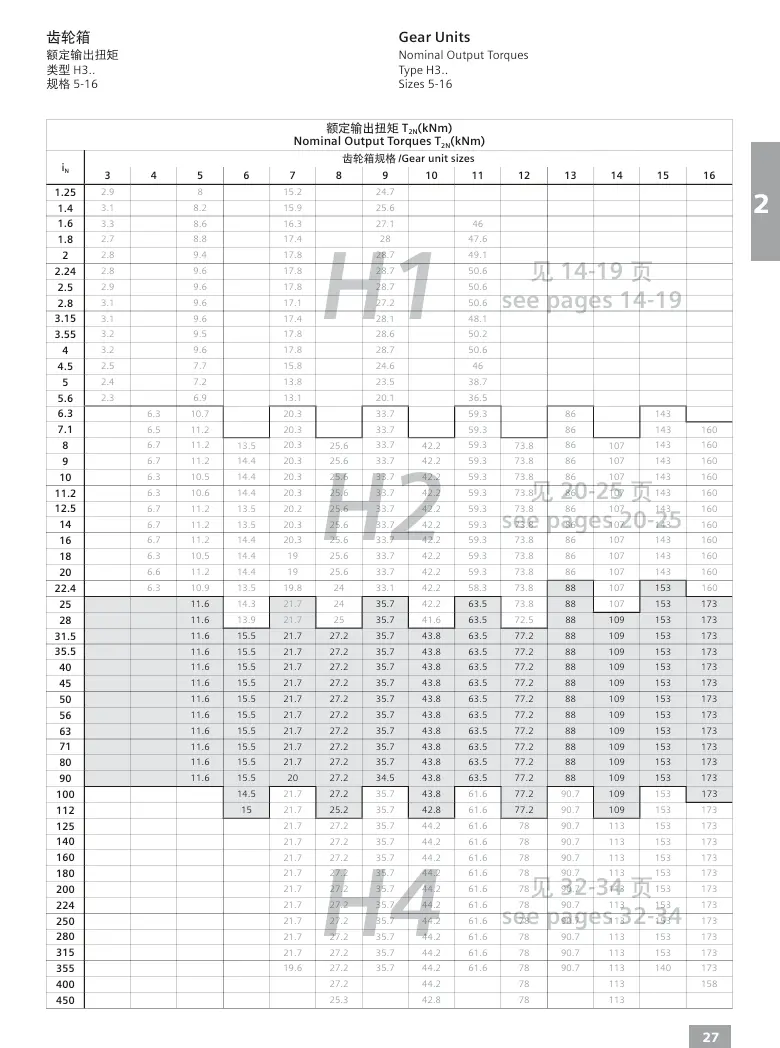

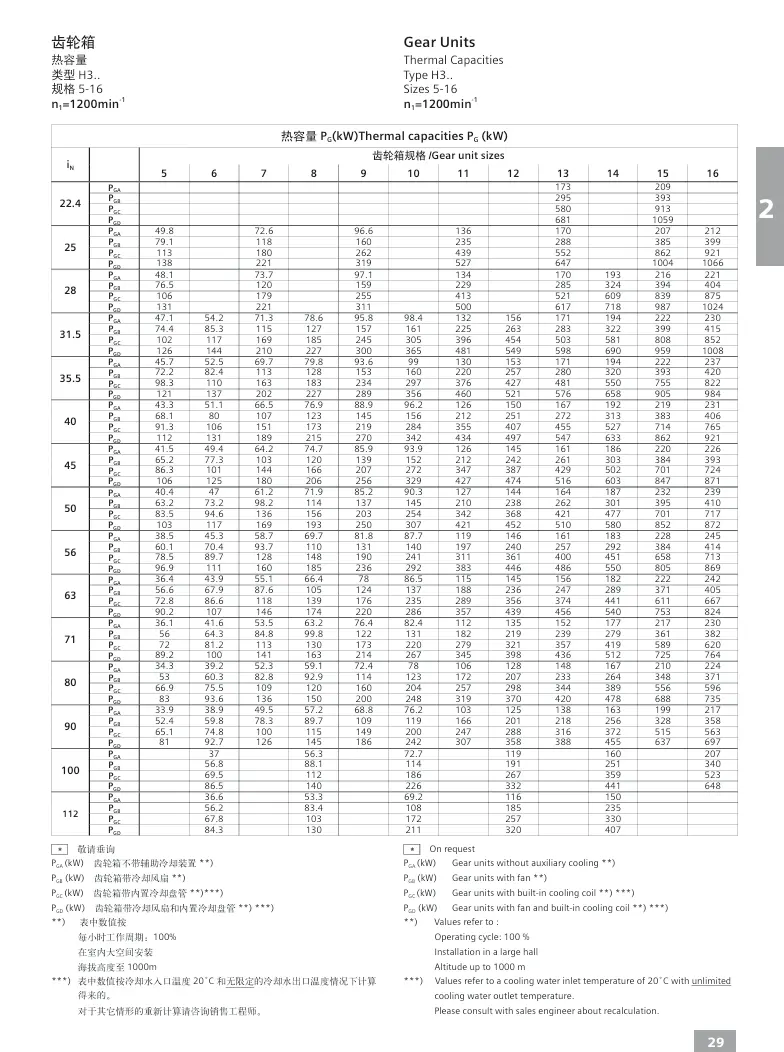

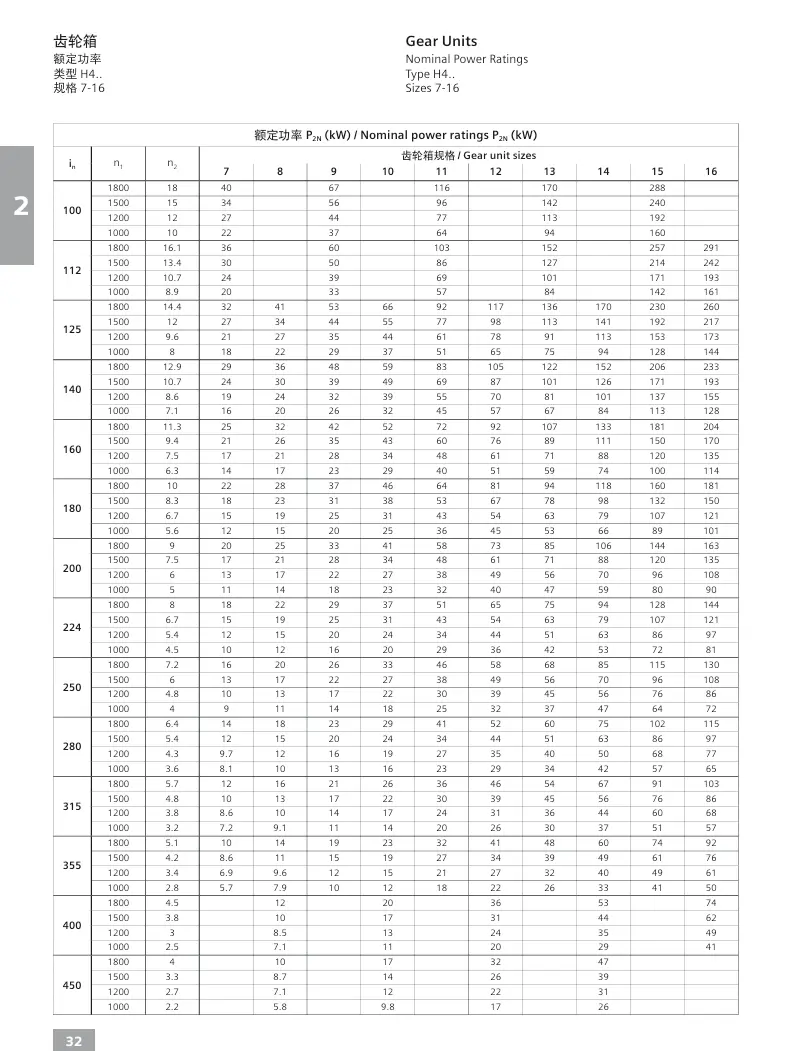

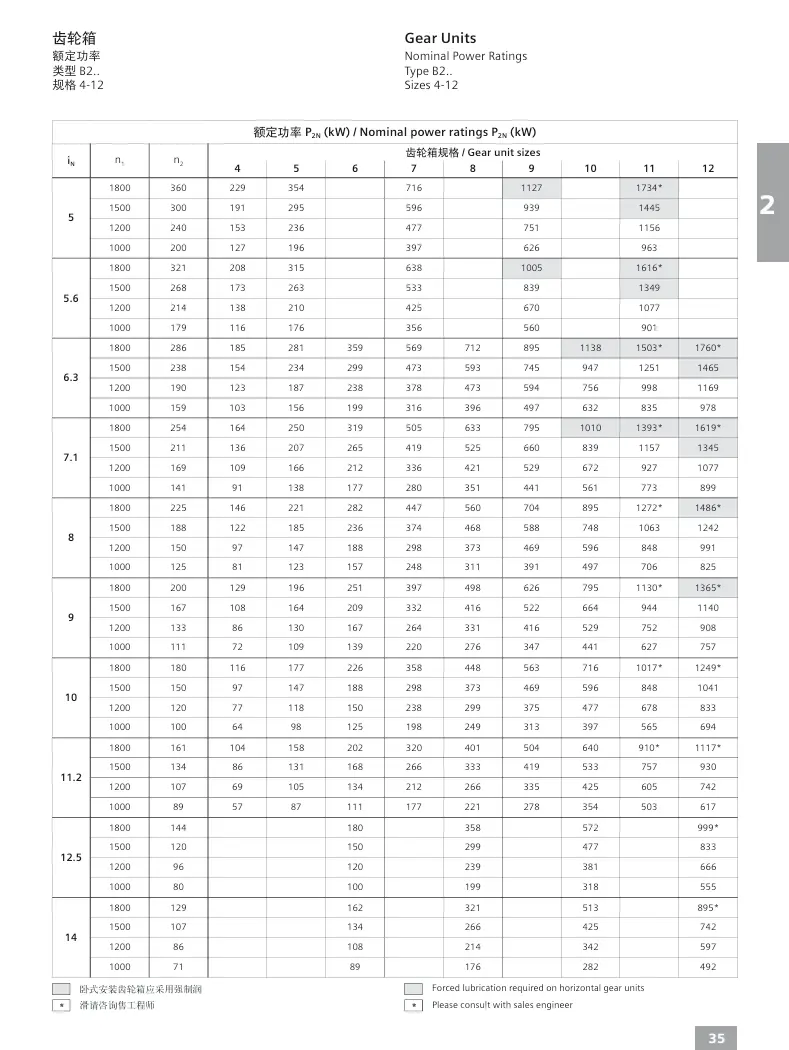

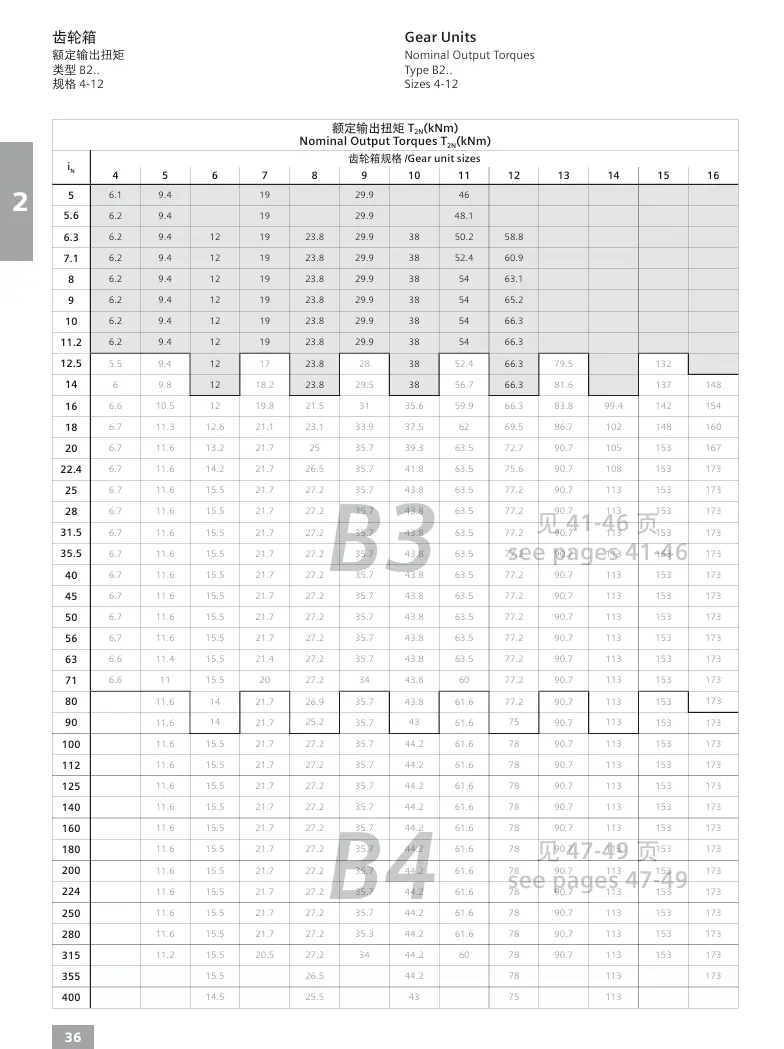

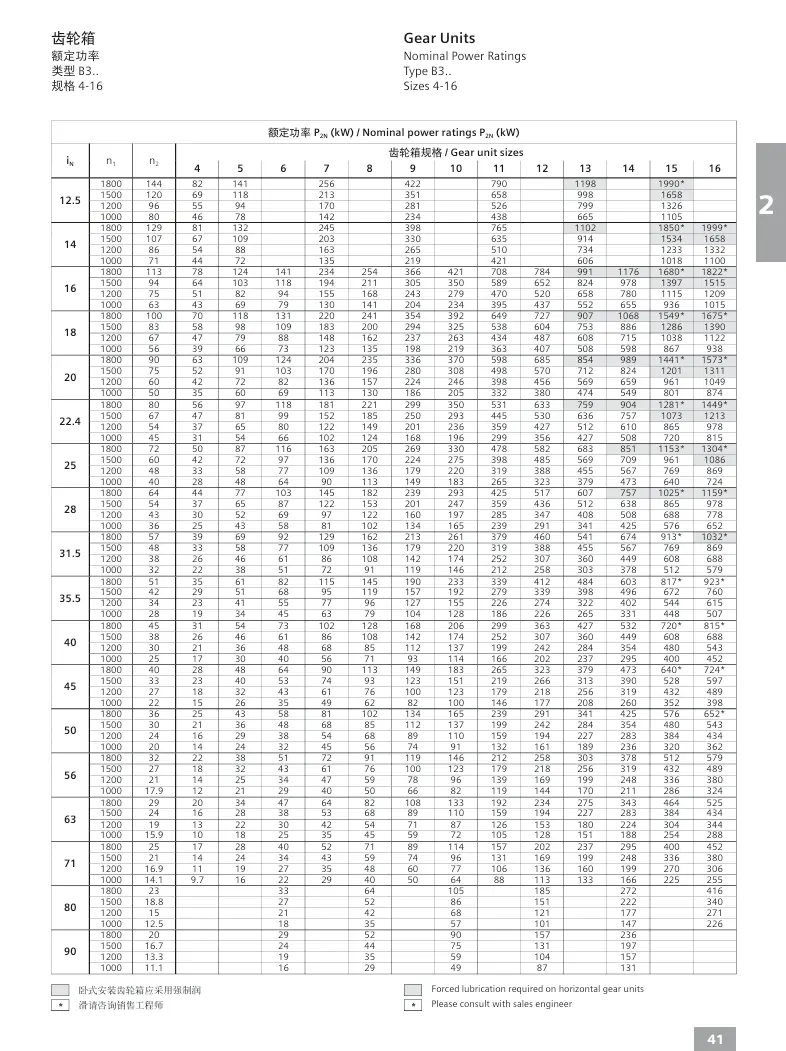

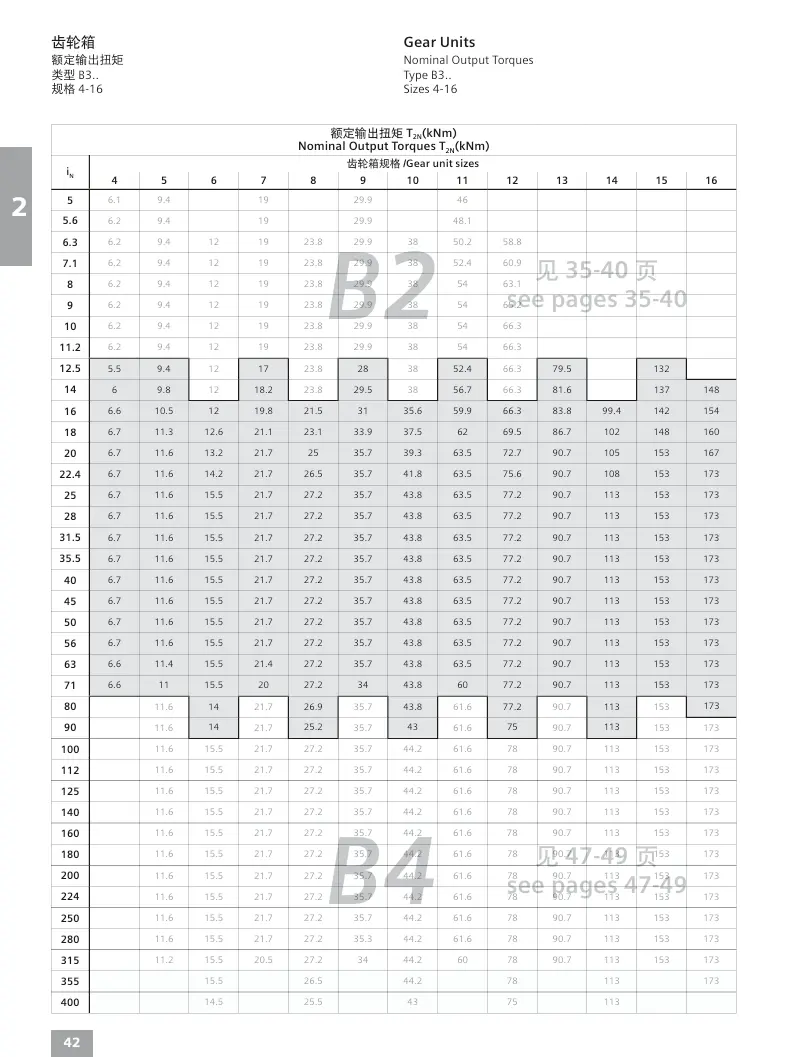

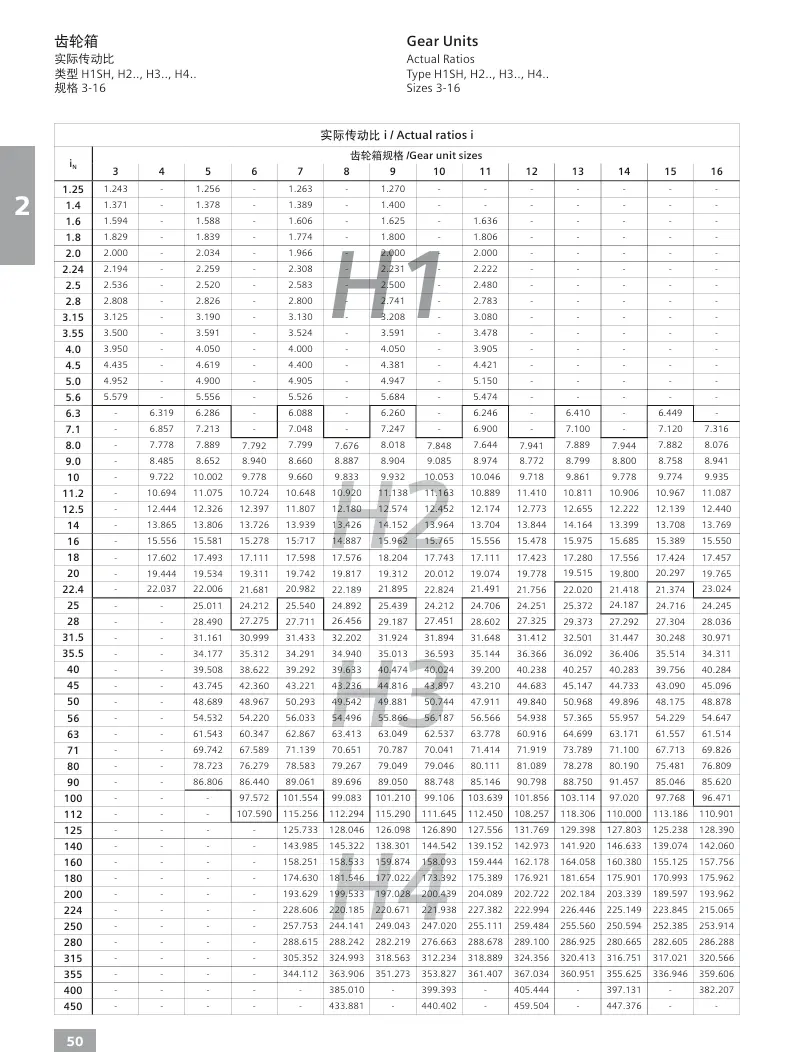

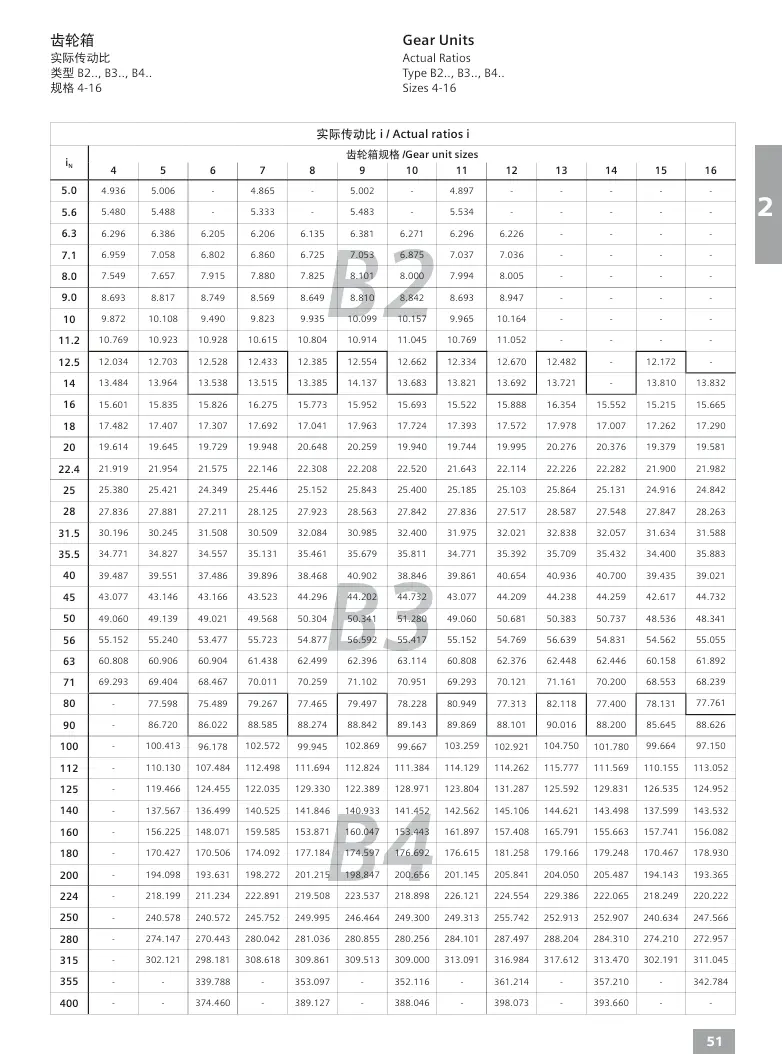

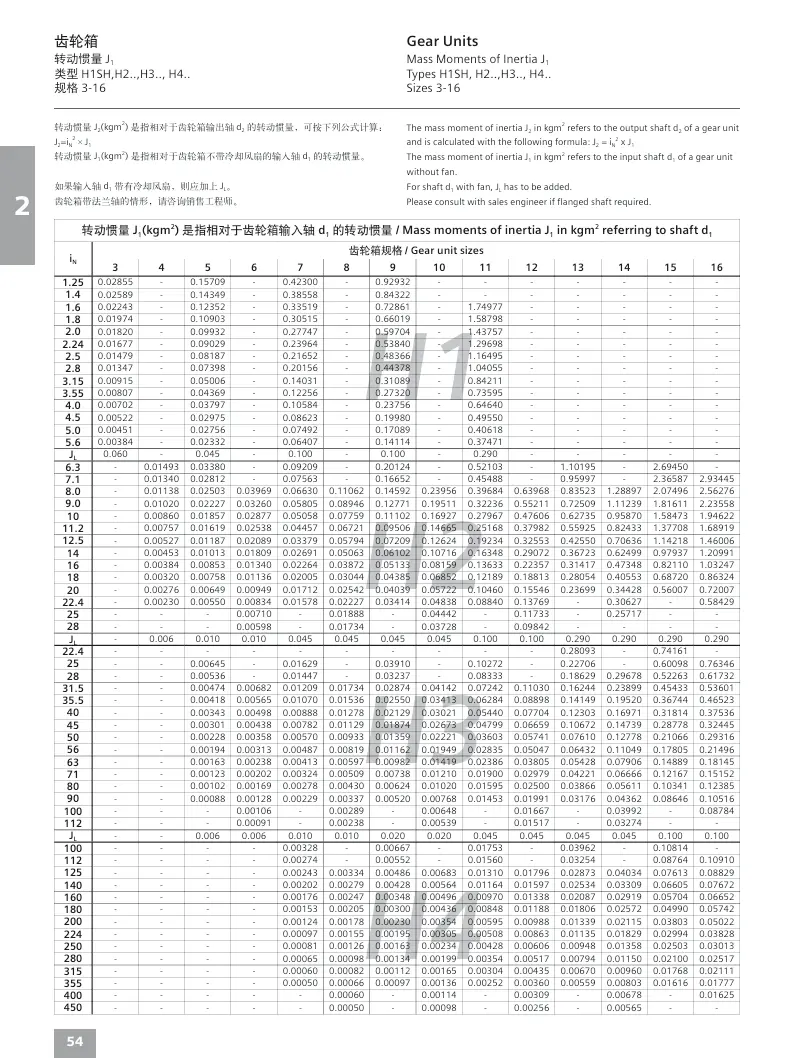

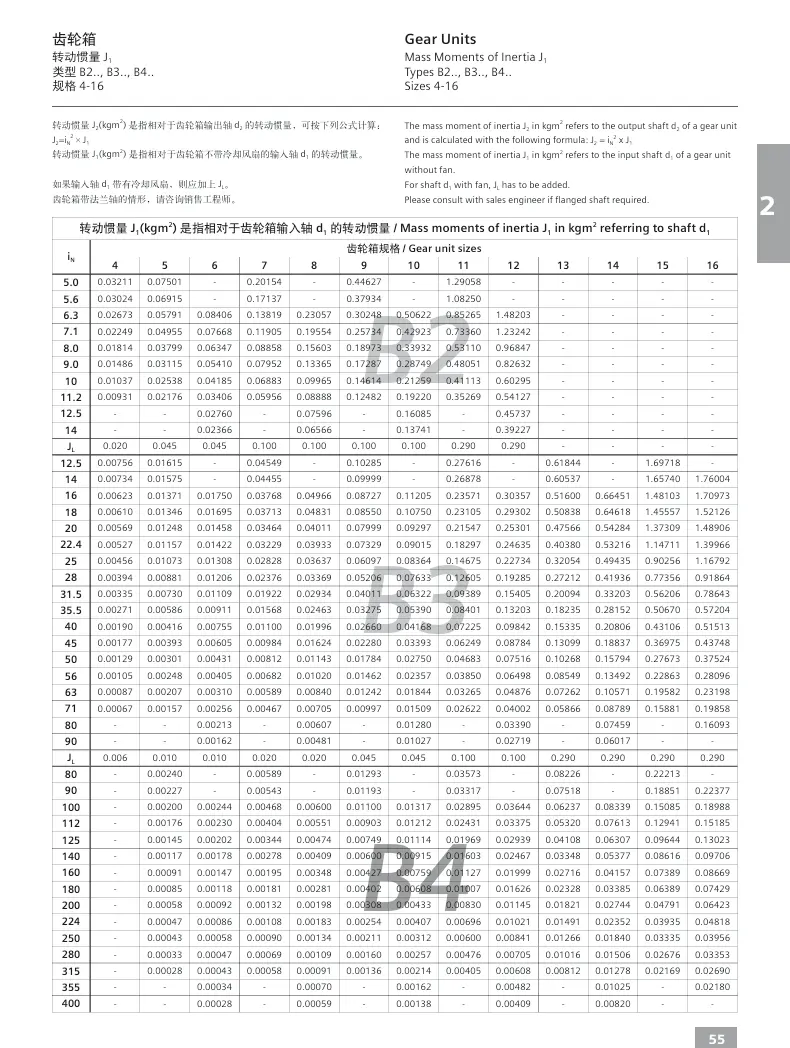

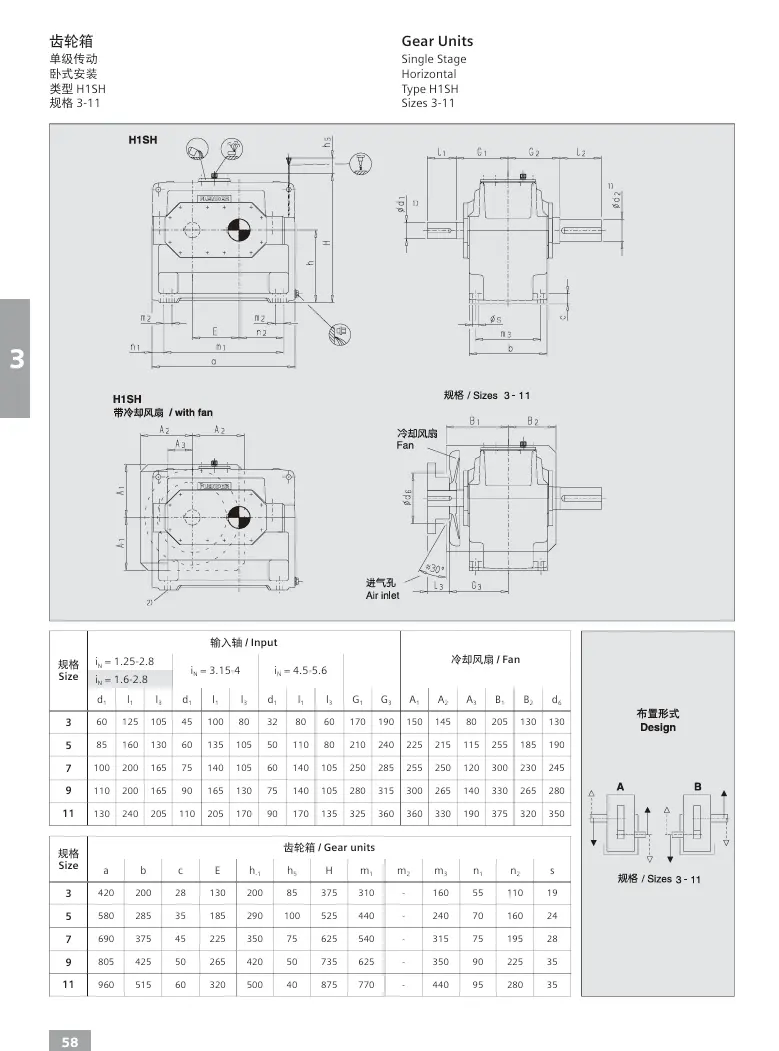

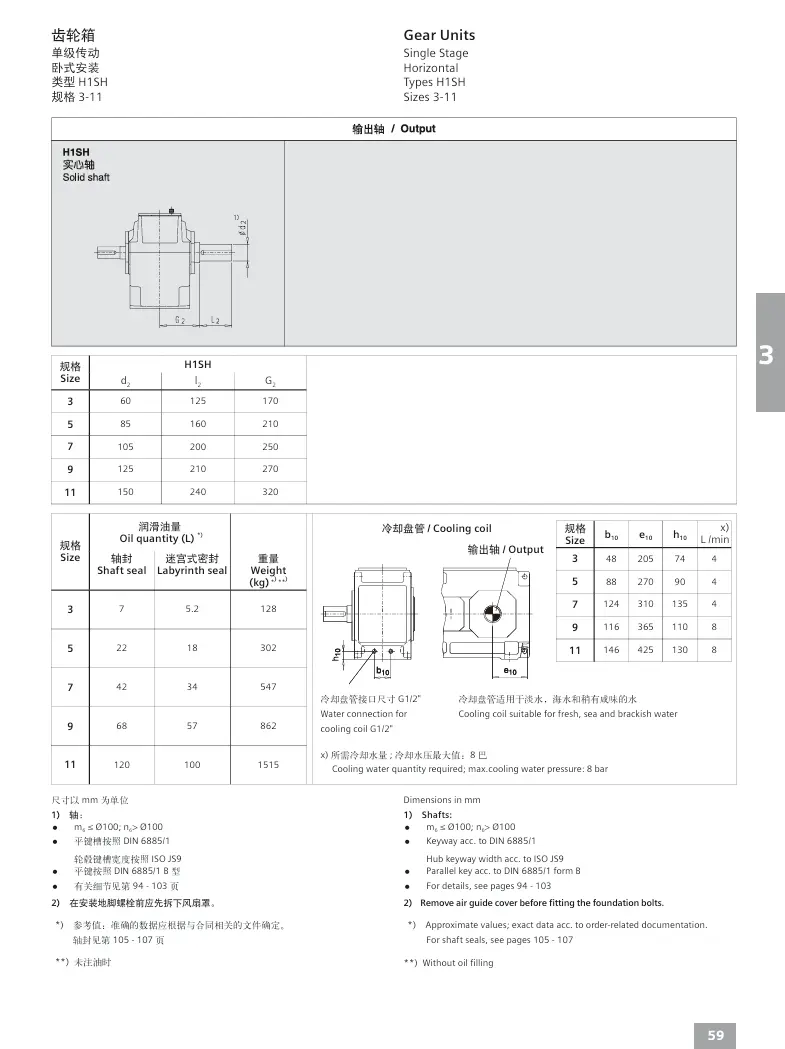

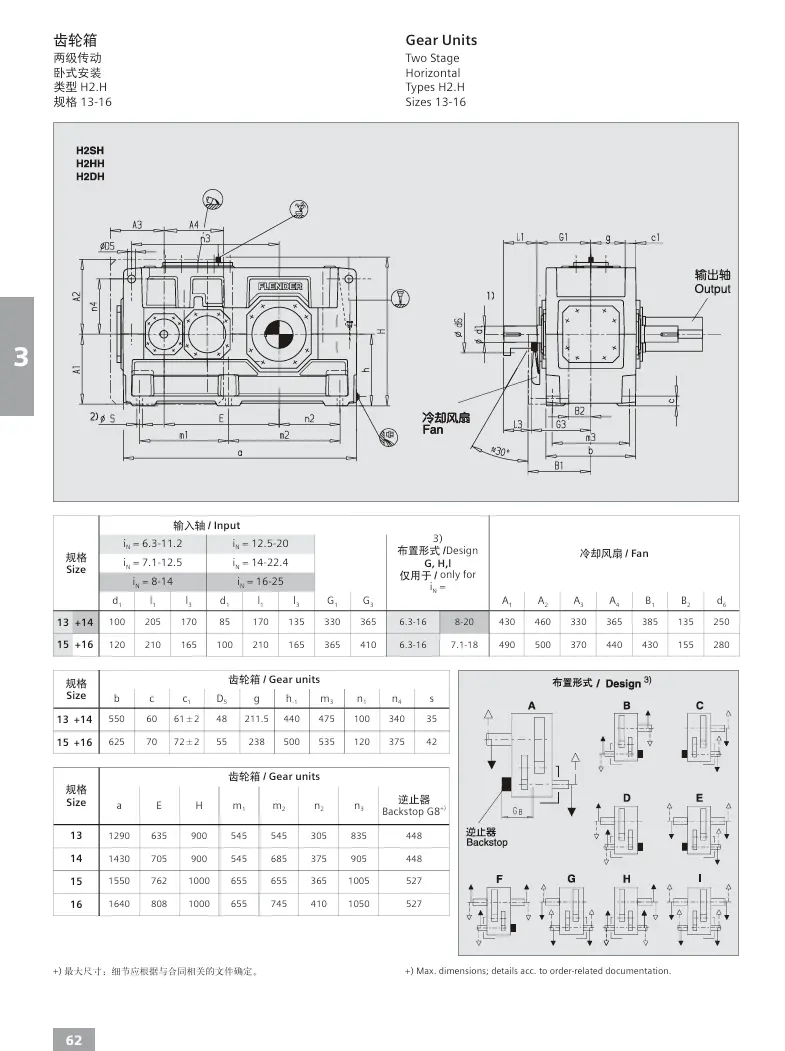

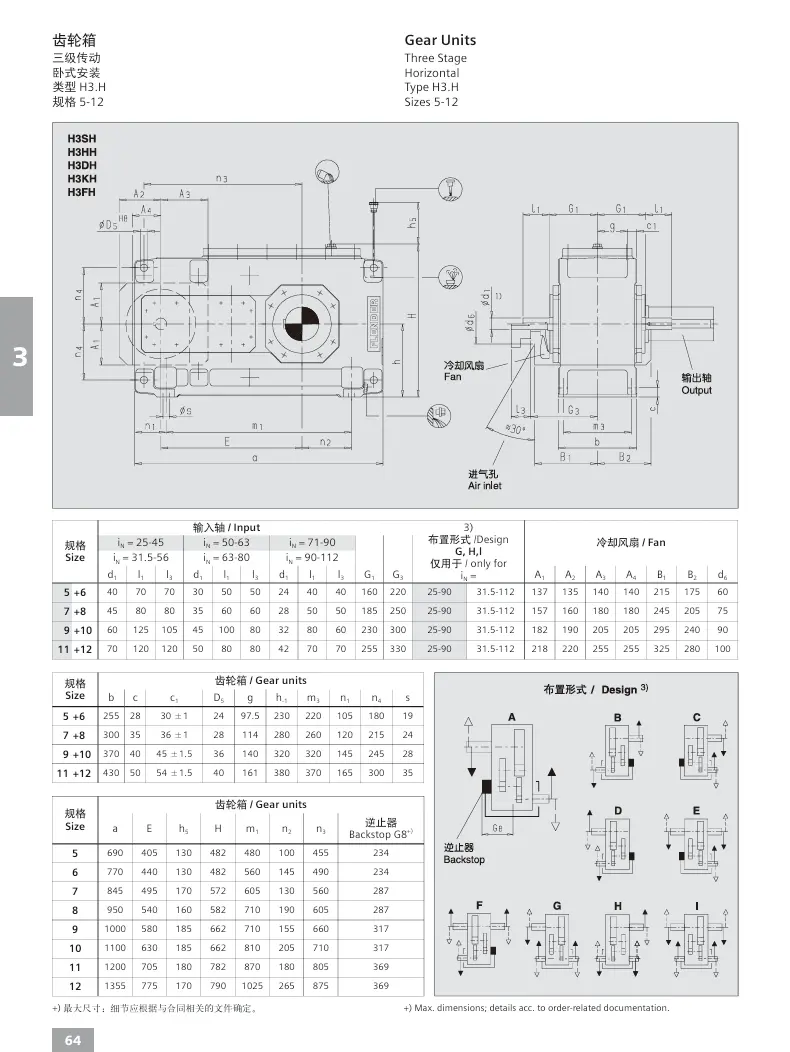

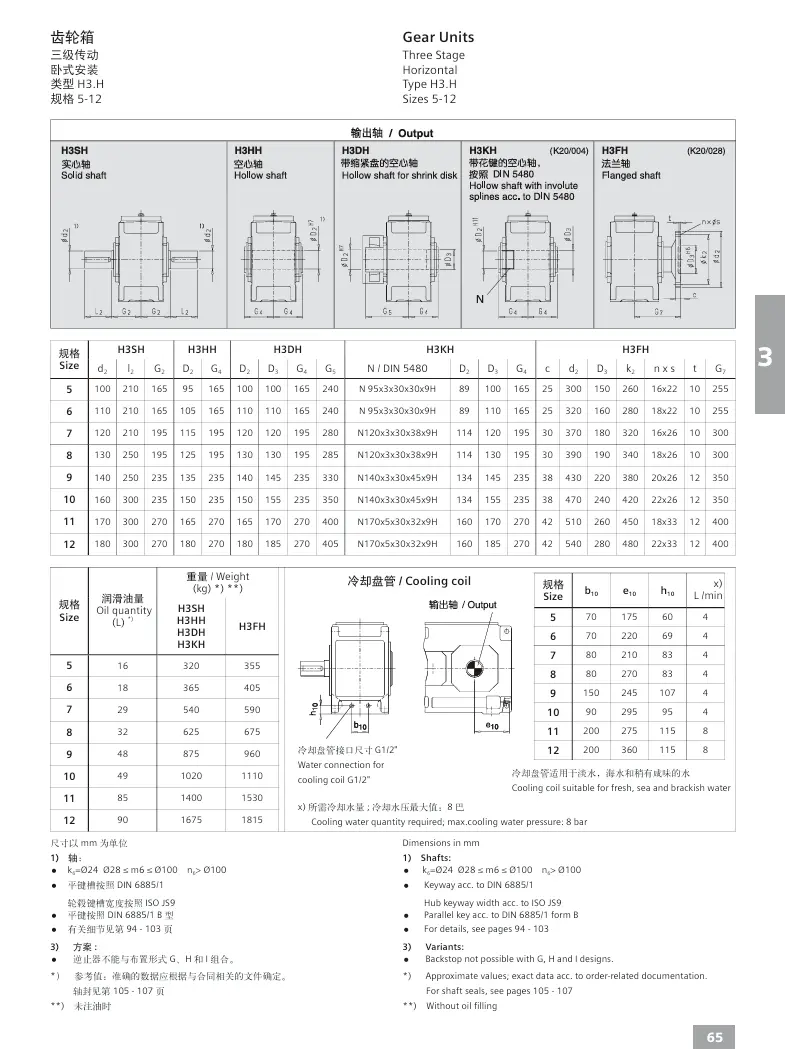

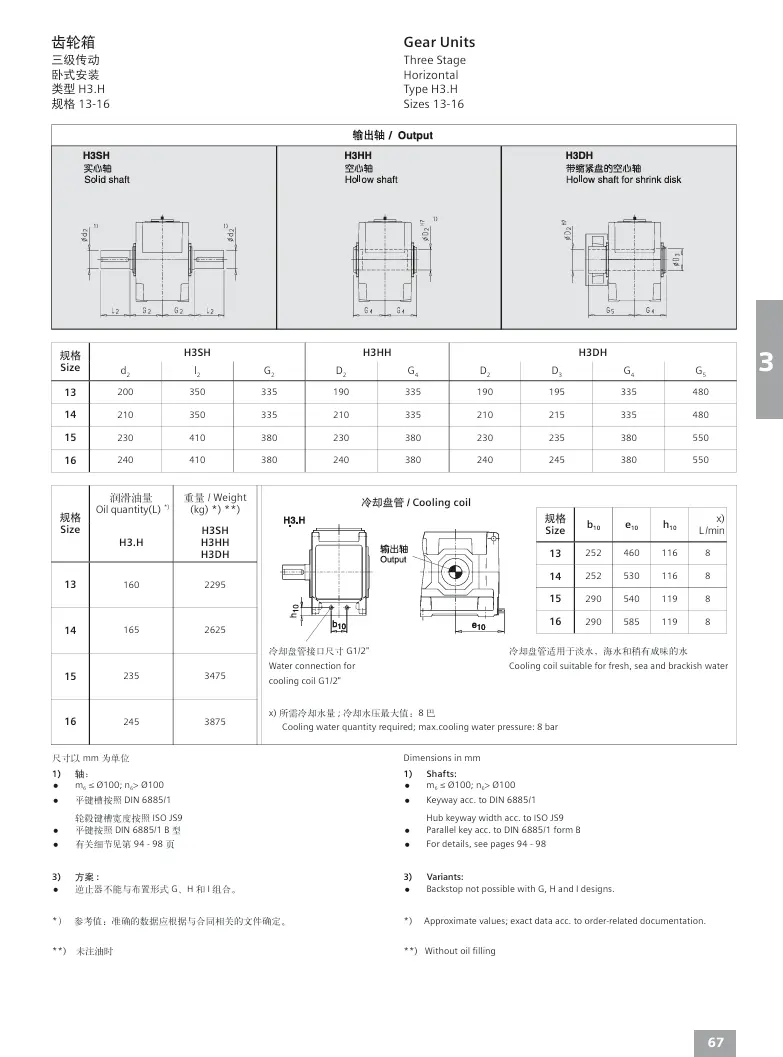

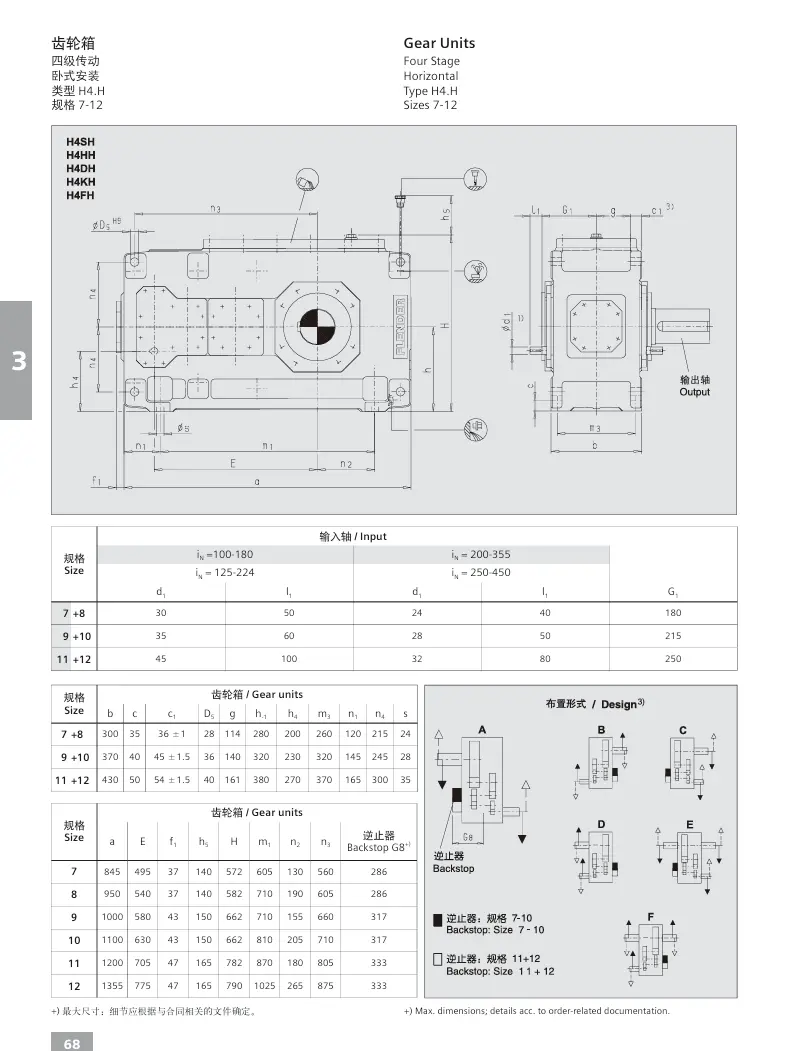

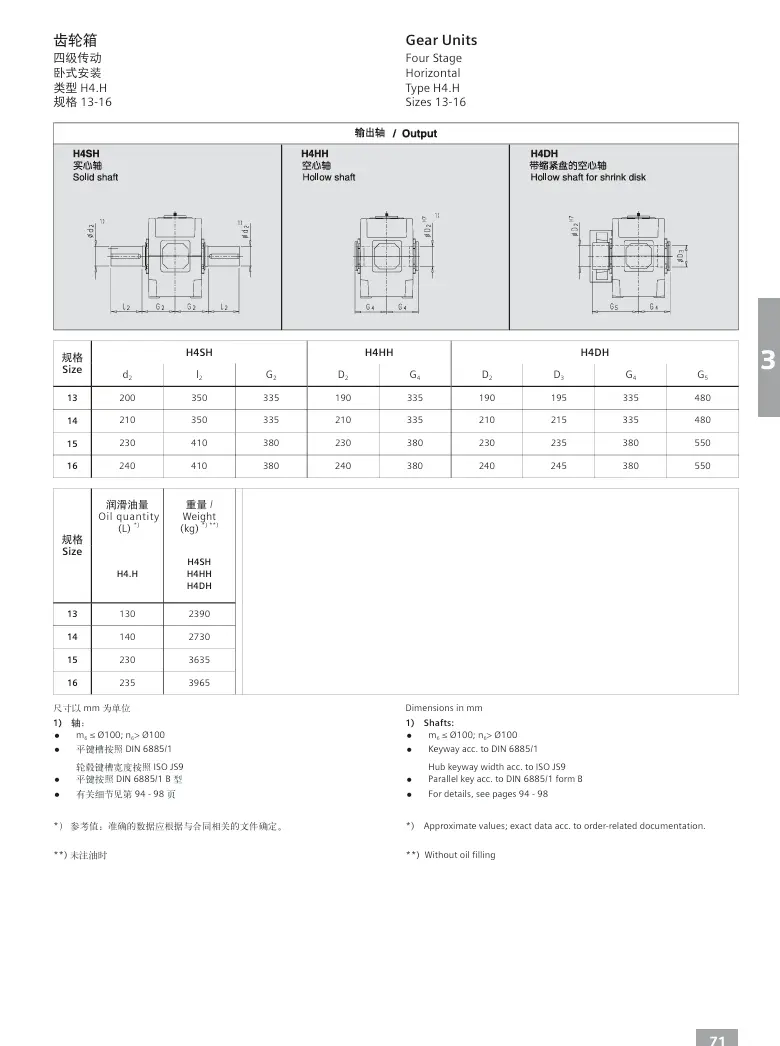

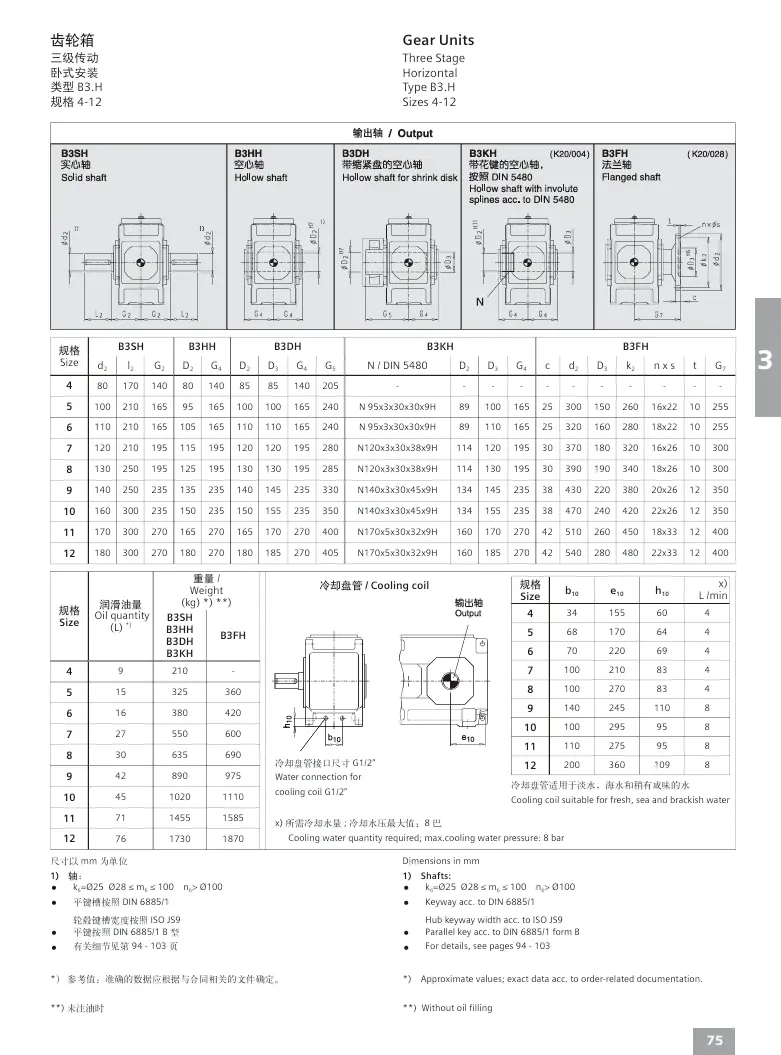

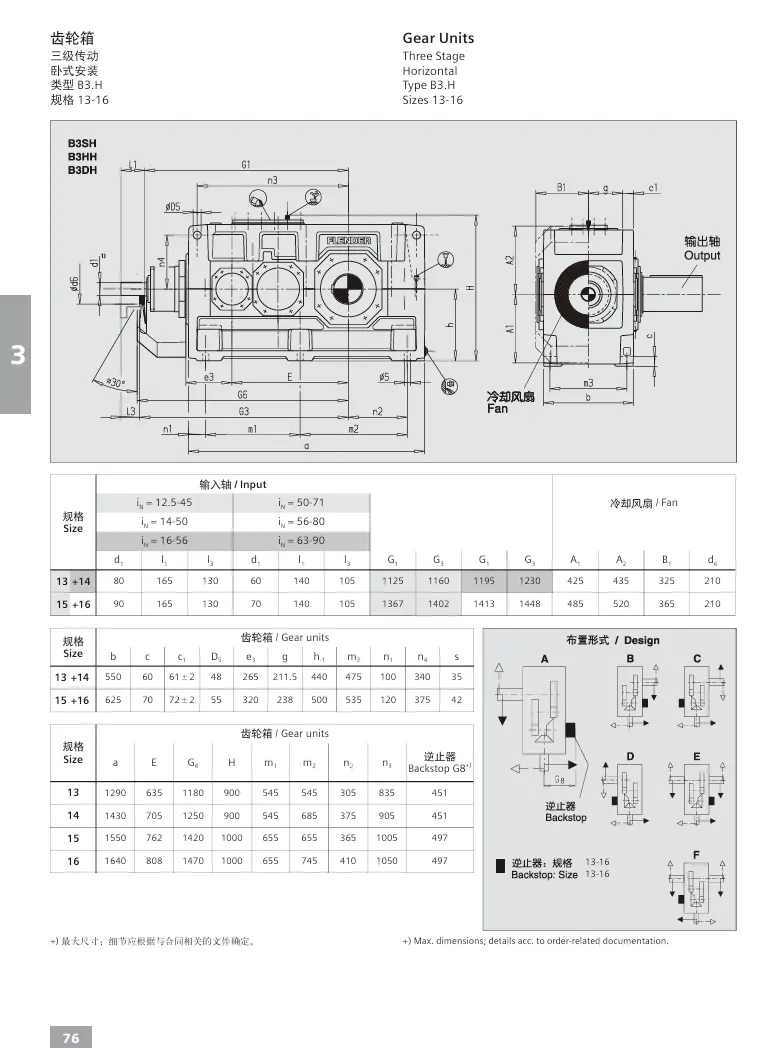

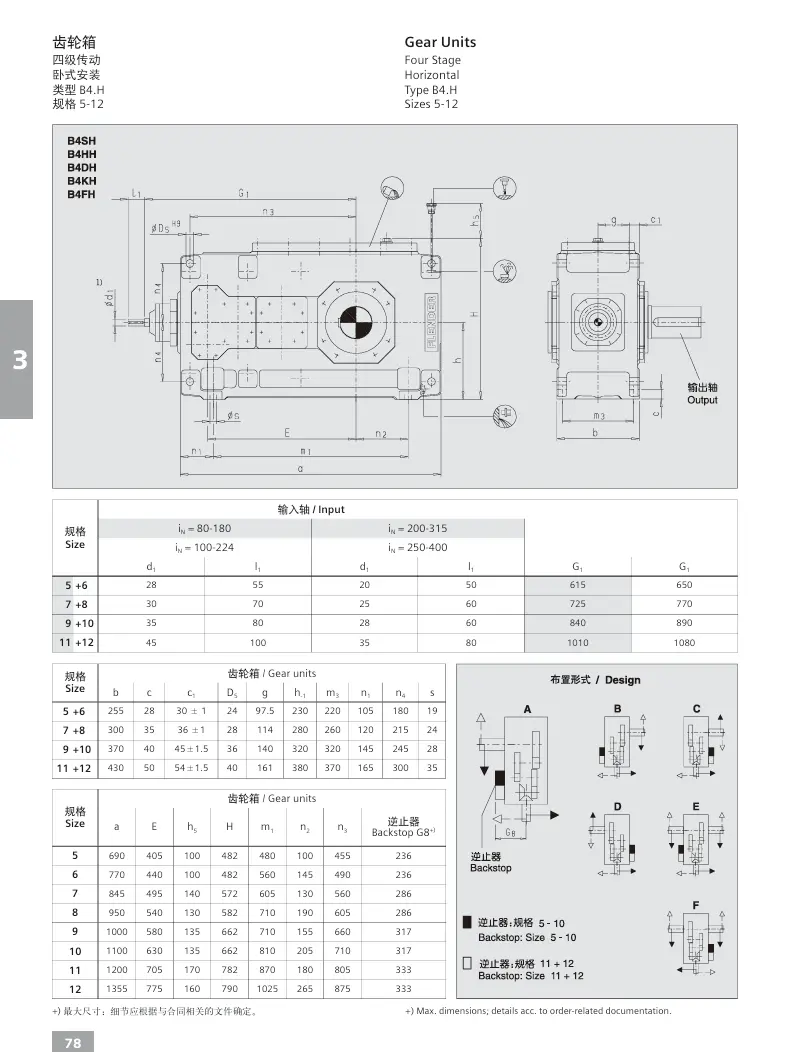

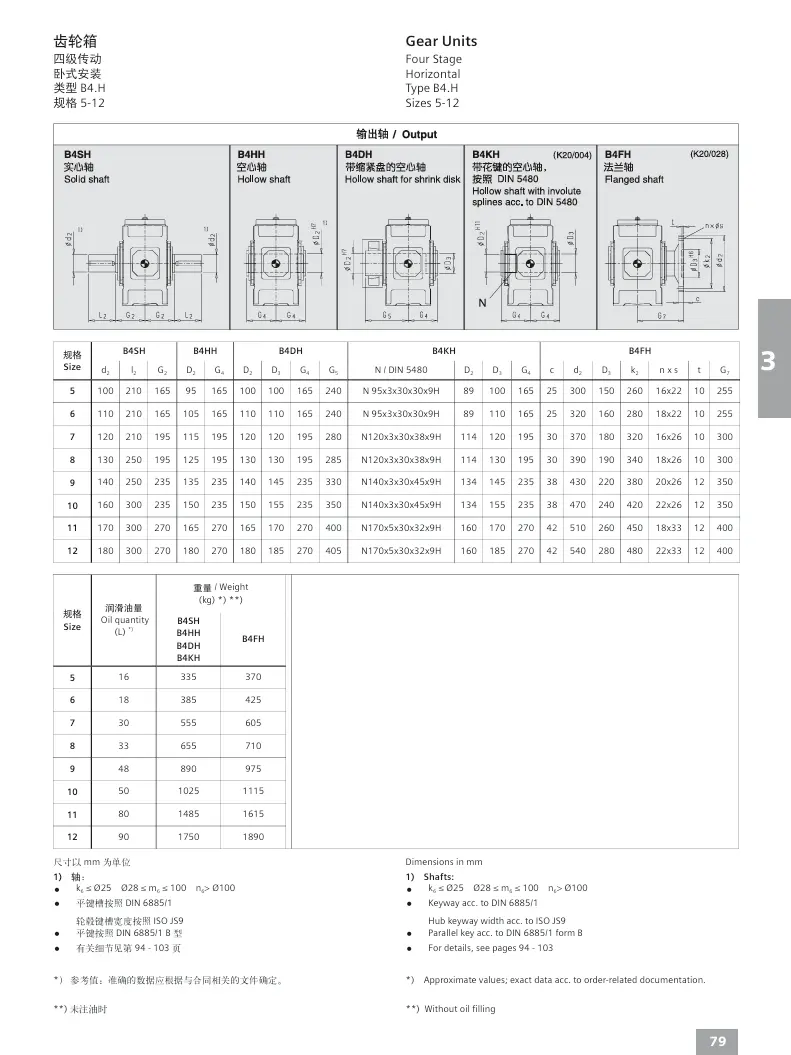

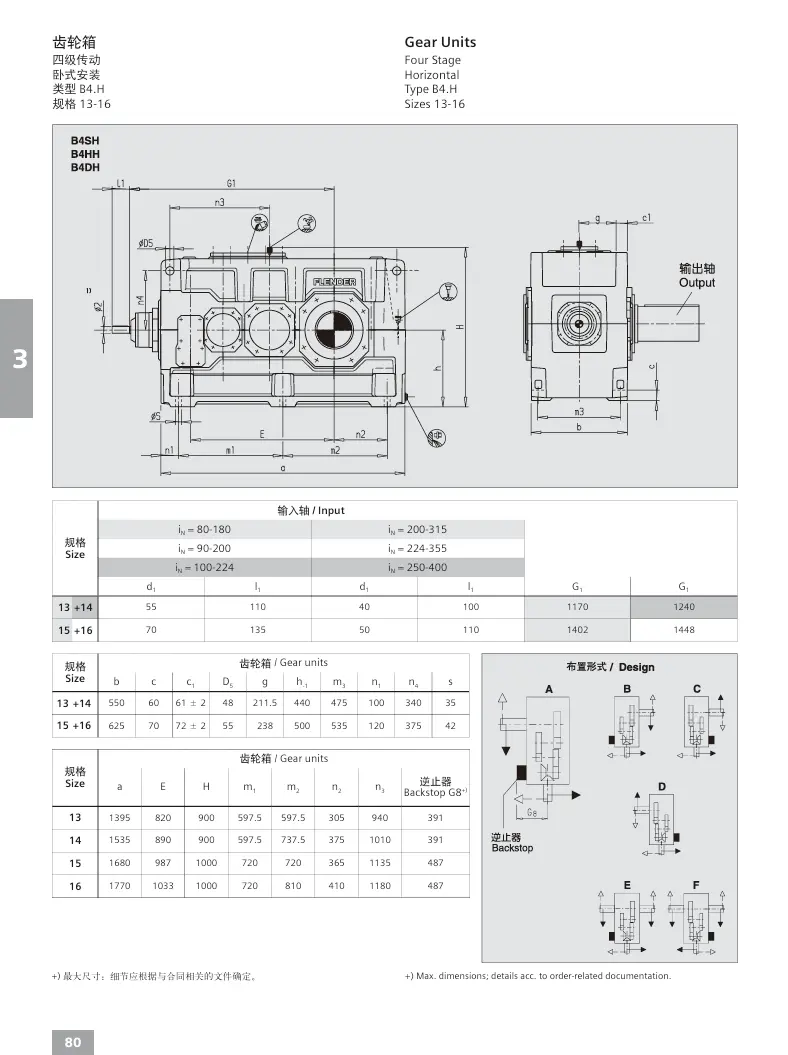

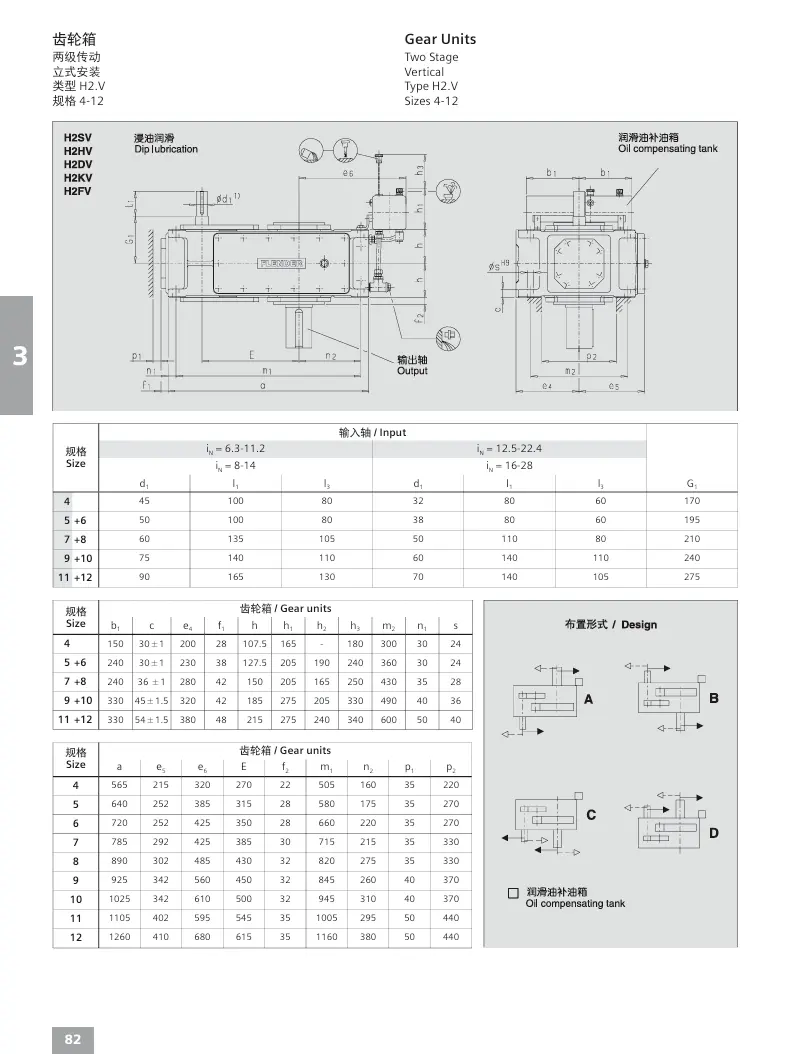

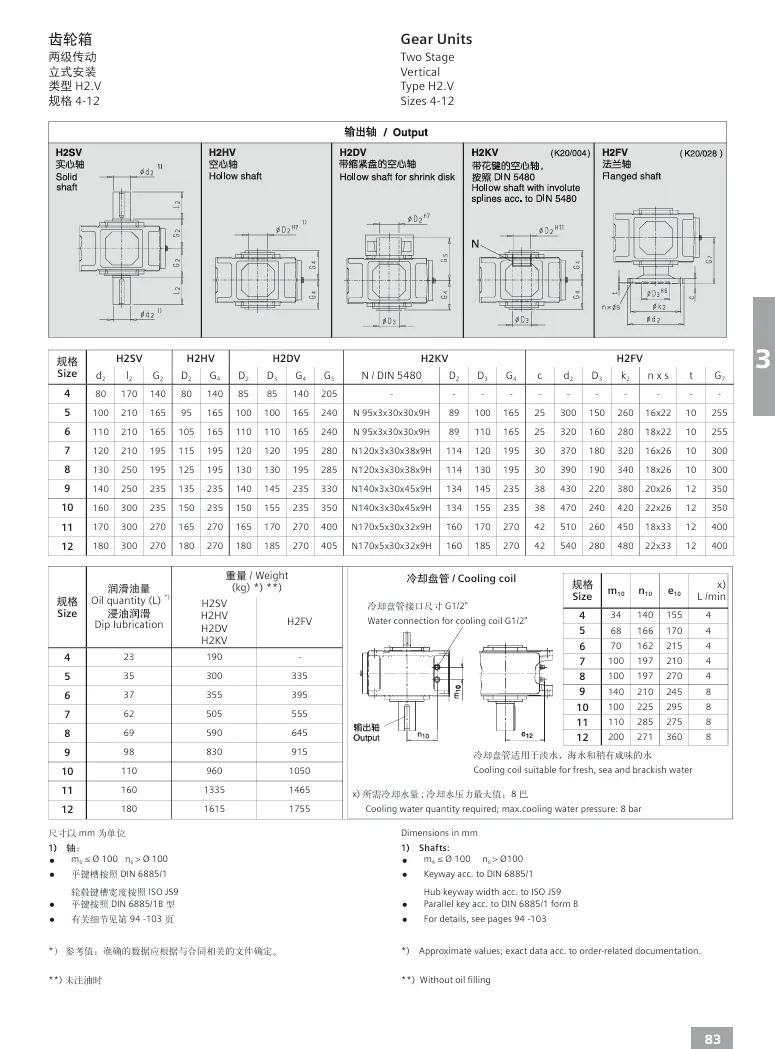

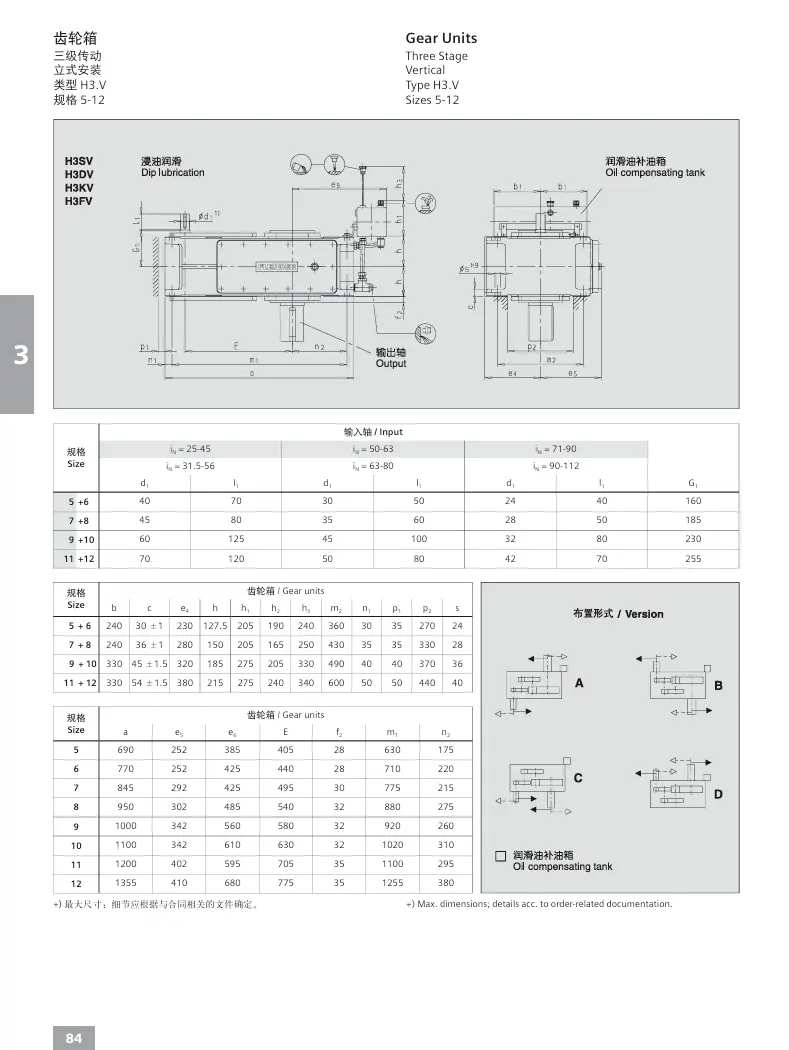

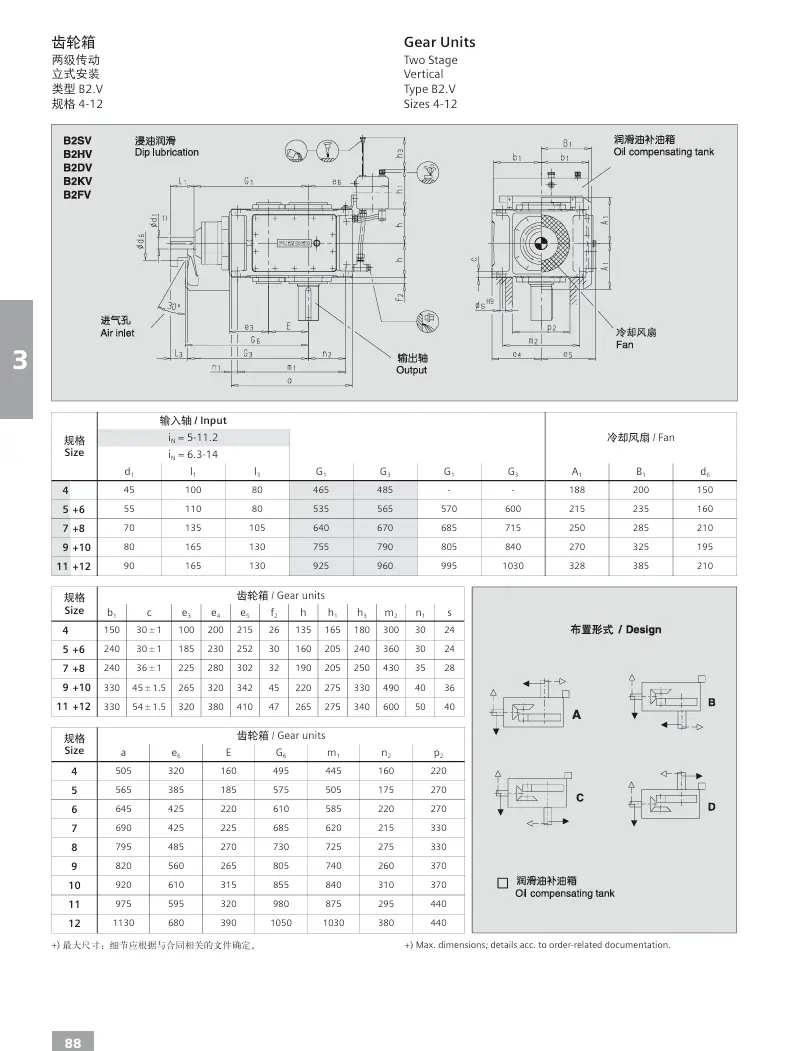

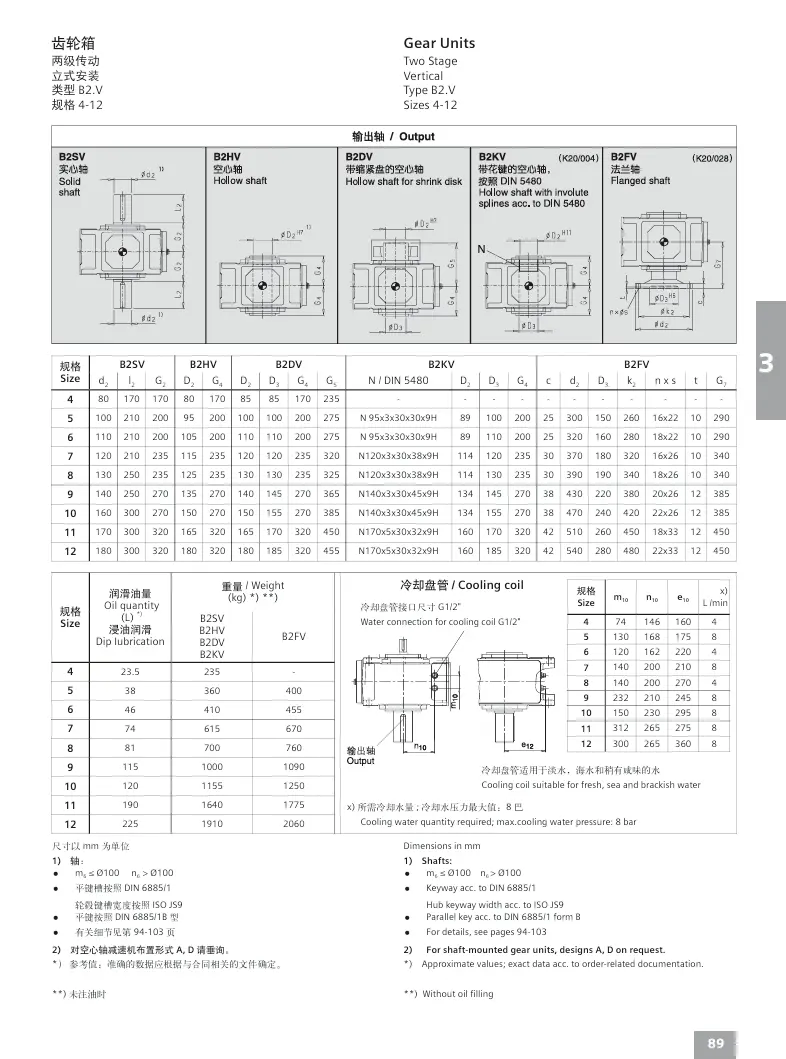

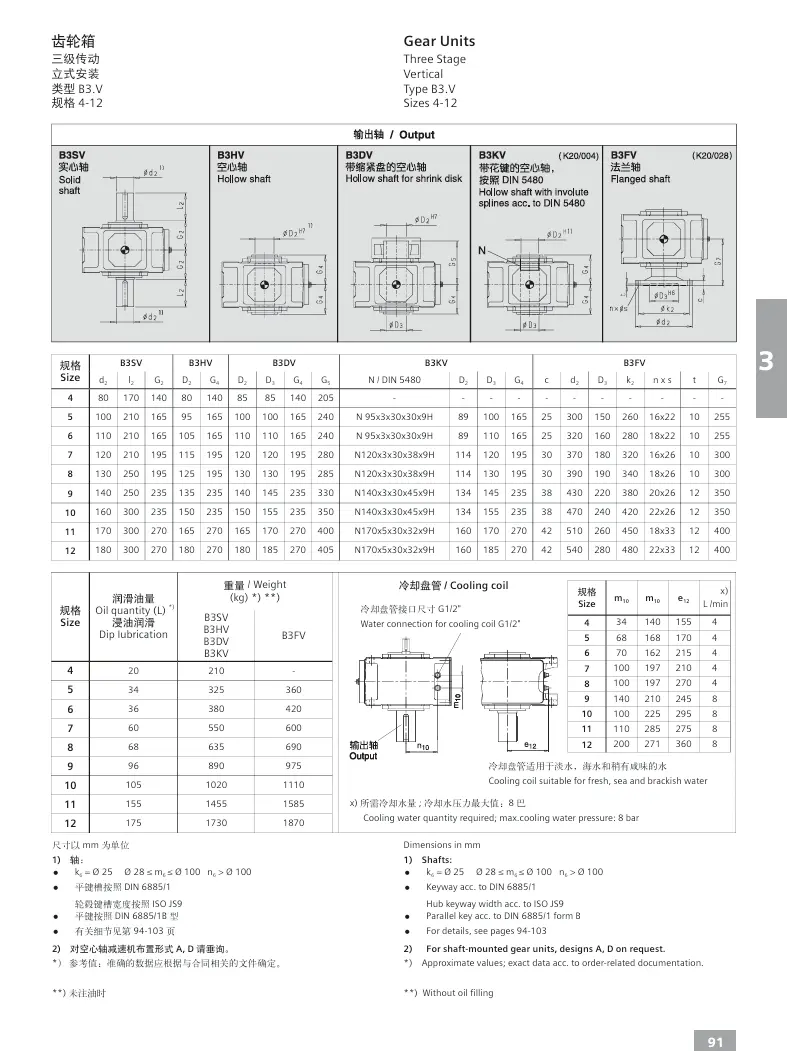

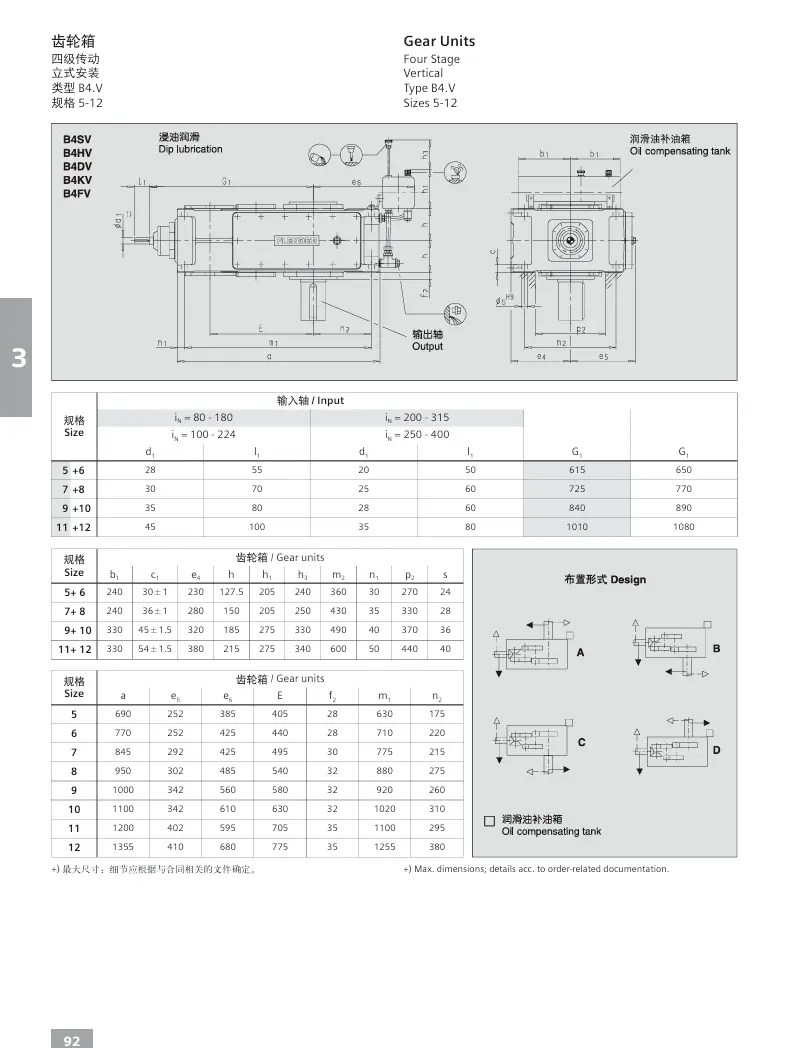

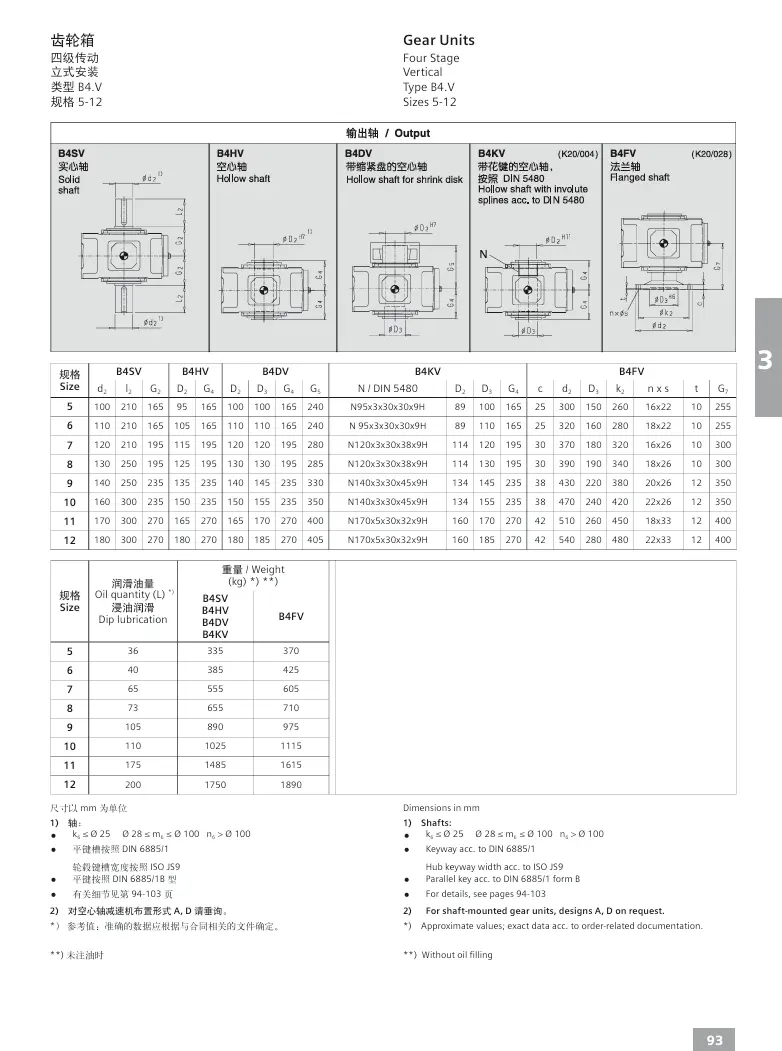

2. The gearbox has 3 to 26 specifications, the deceleration transmission stage has 1 to 4 stages, and the speed ratio is 1.25to450.

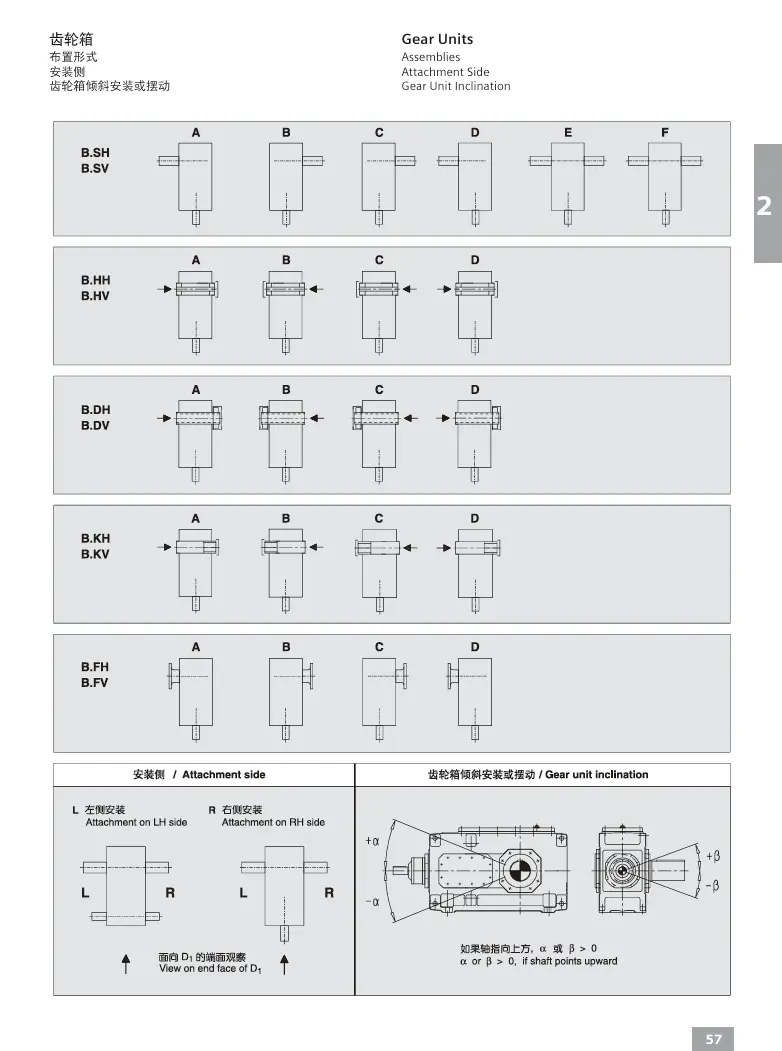

3. Installation method: base installation, hollow shaft installation, swing base installation, torque arm installation.

4. Input method: motor connection flange and shaft input.

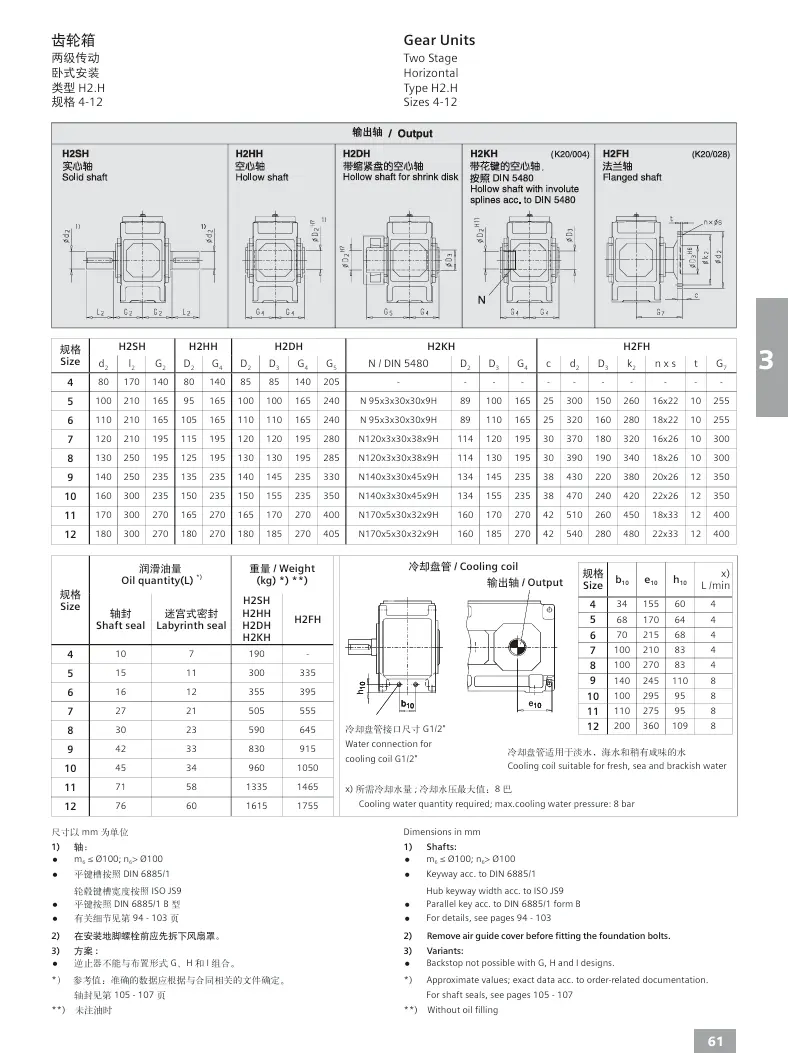

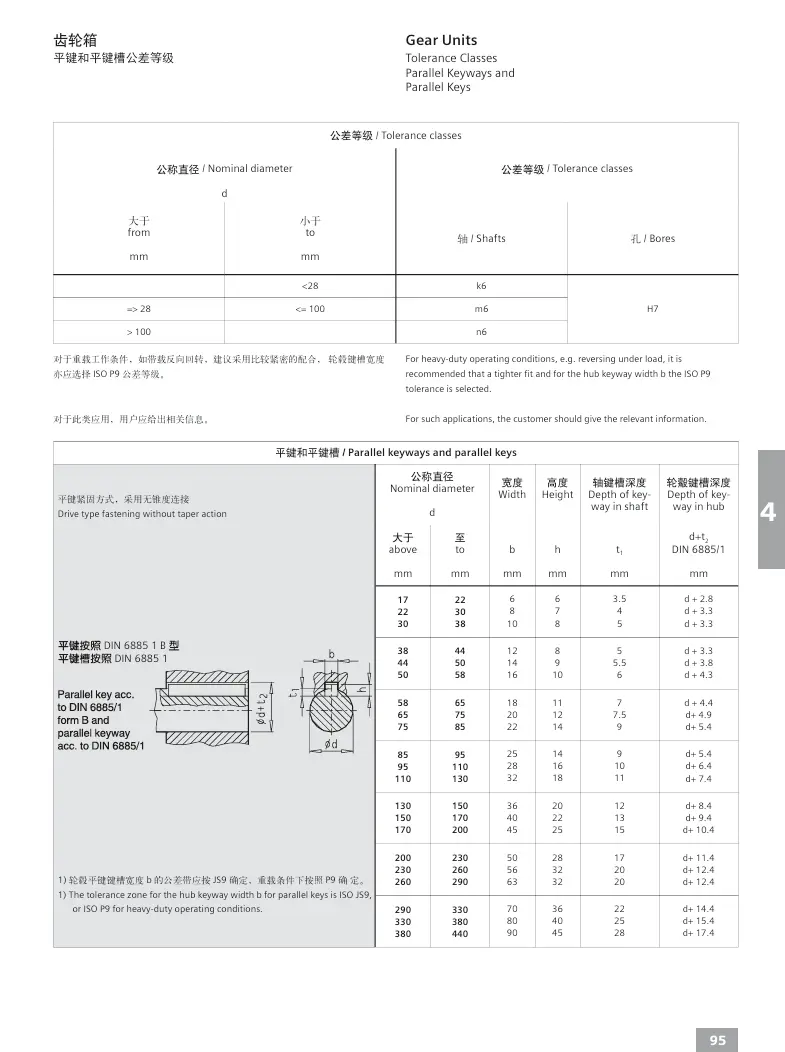

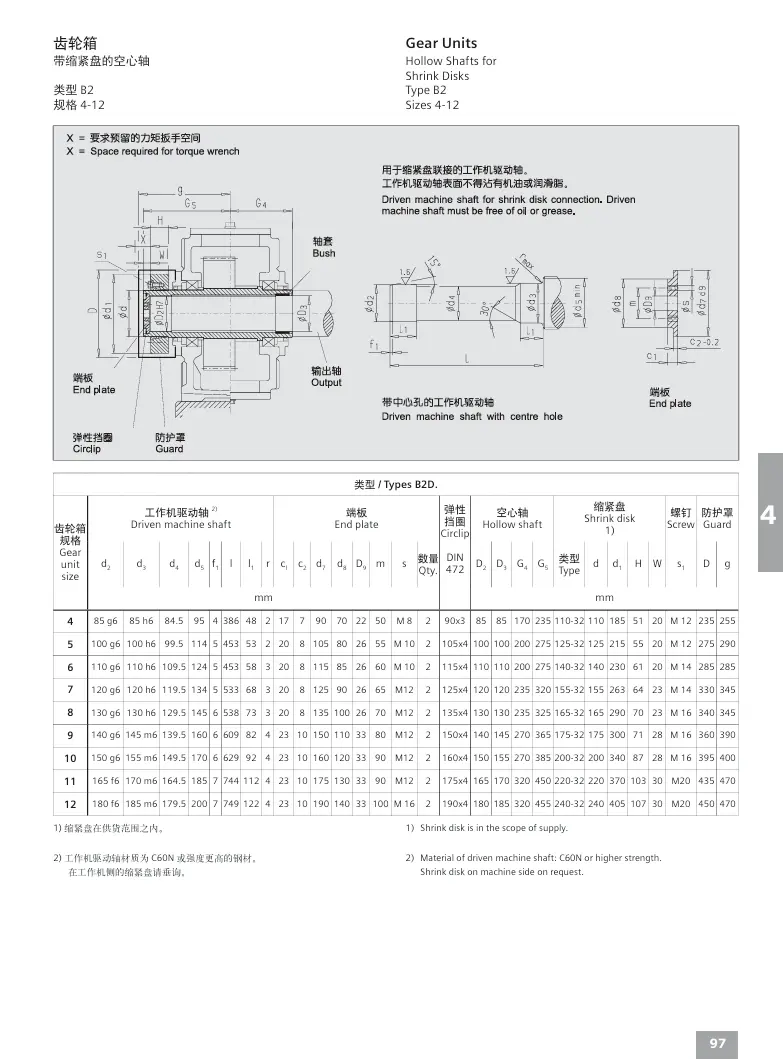

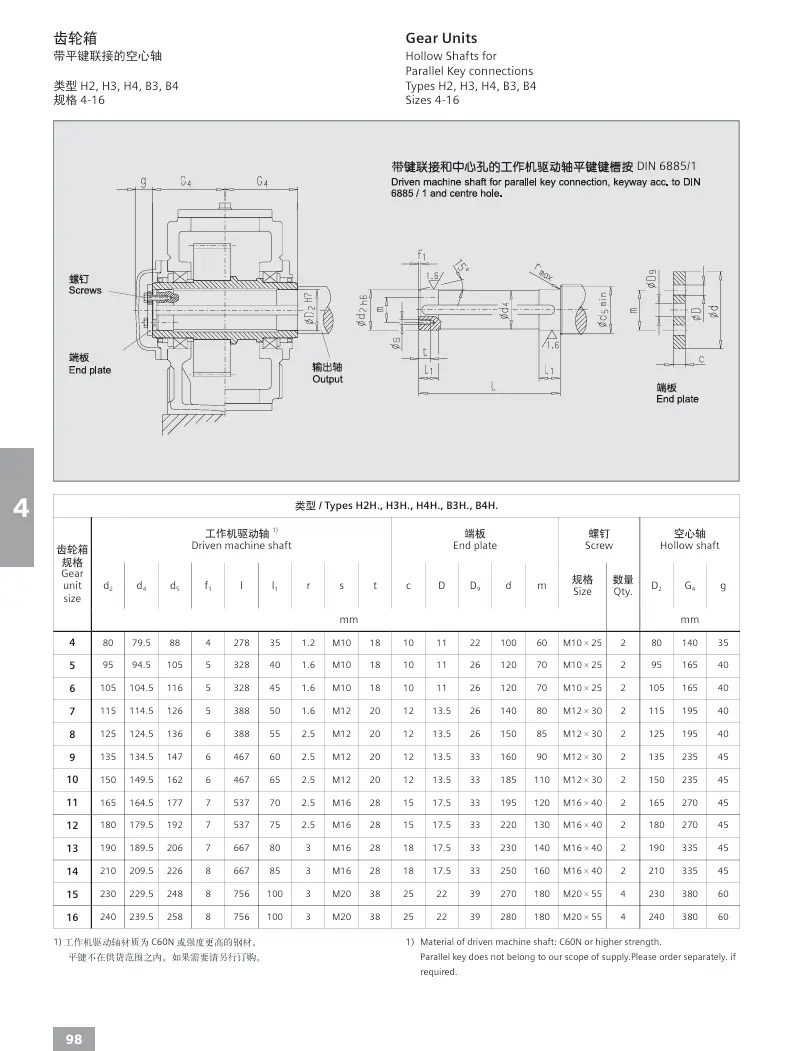

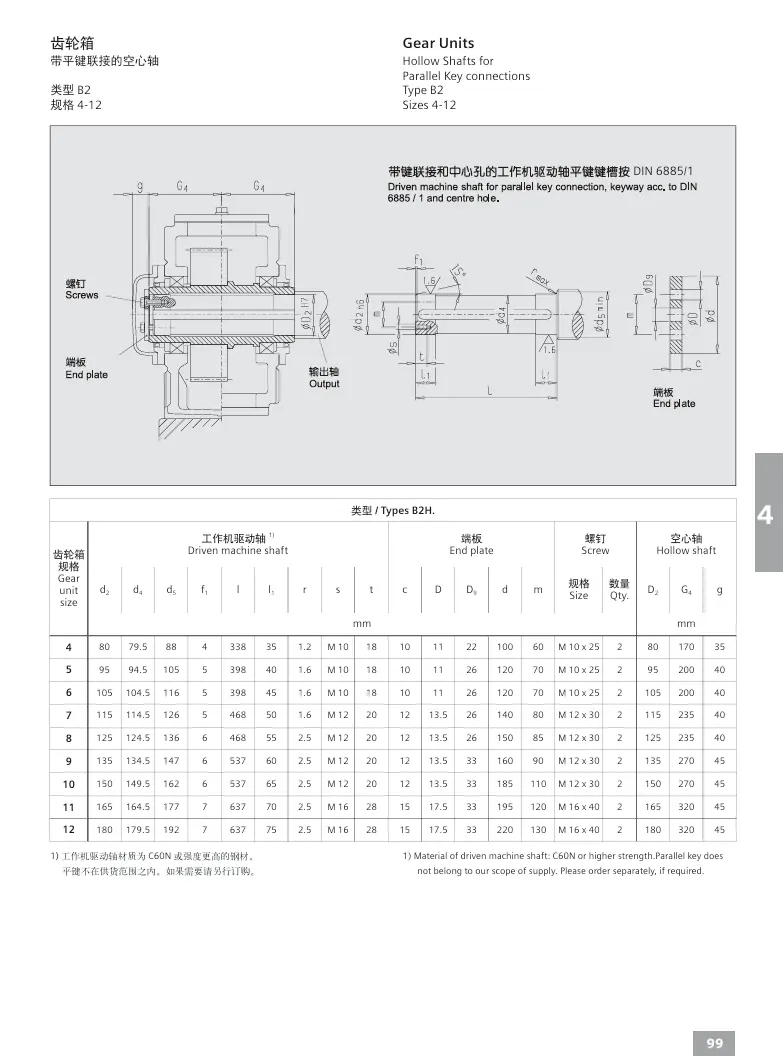

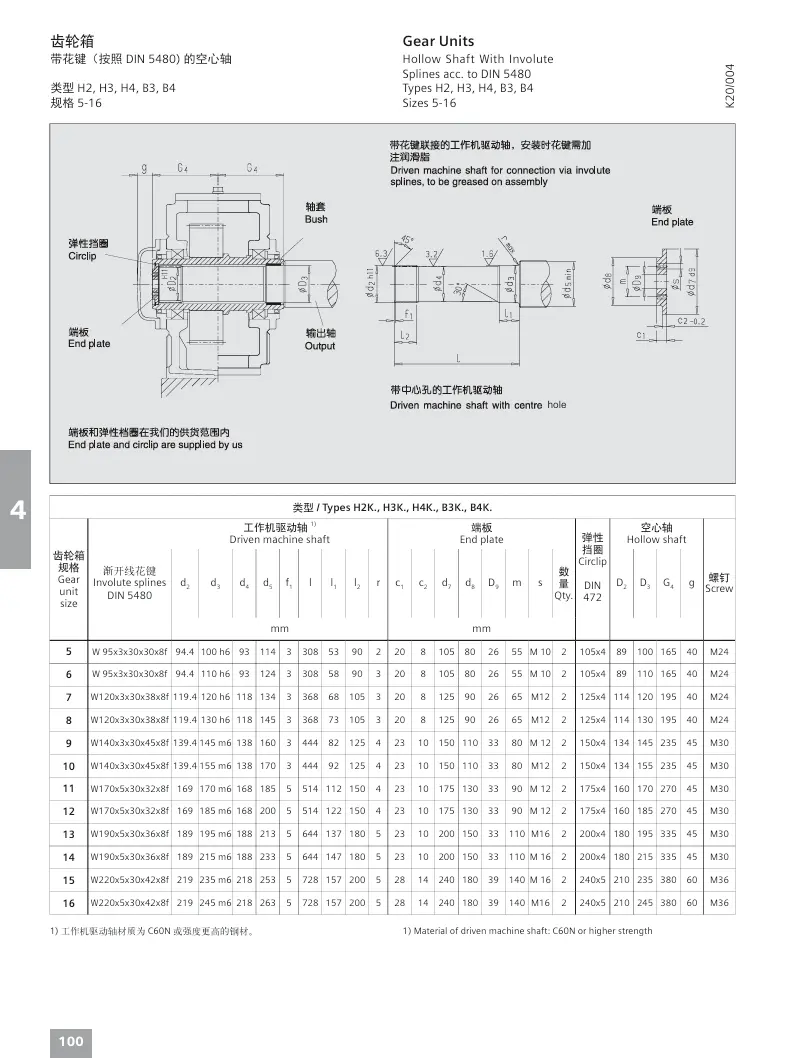

5. Output method: solid shaft with flat key, hollow shaft with flat key, hollow shaft with expansion disc connection, hollow shaft with spline connection, solid shaft with spline connection and solid shaft with flange connection.

6. Backstop can be equipped according to customer requirements.Combined with the R and K series to obtain a greater speed ratio.

Device method: foot device, flange device, shaft-mounted device, device with locking disc

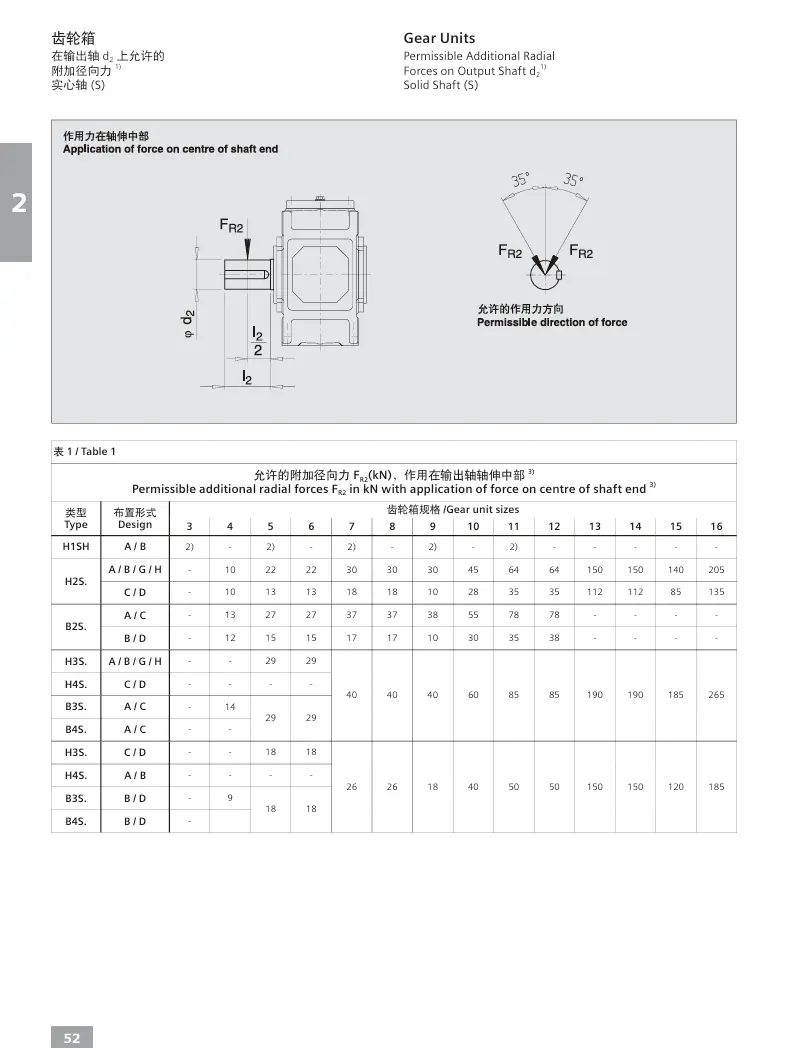

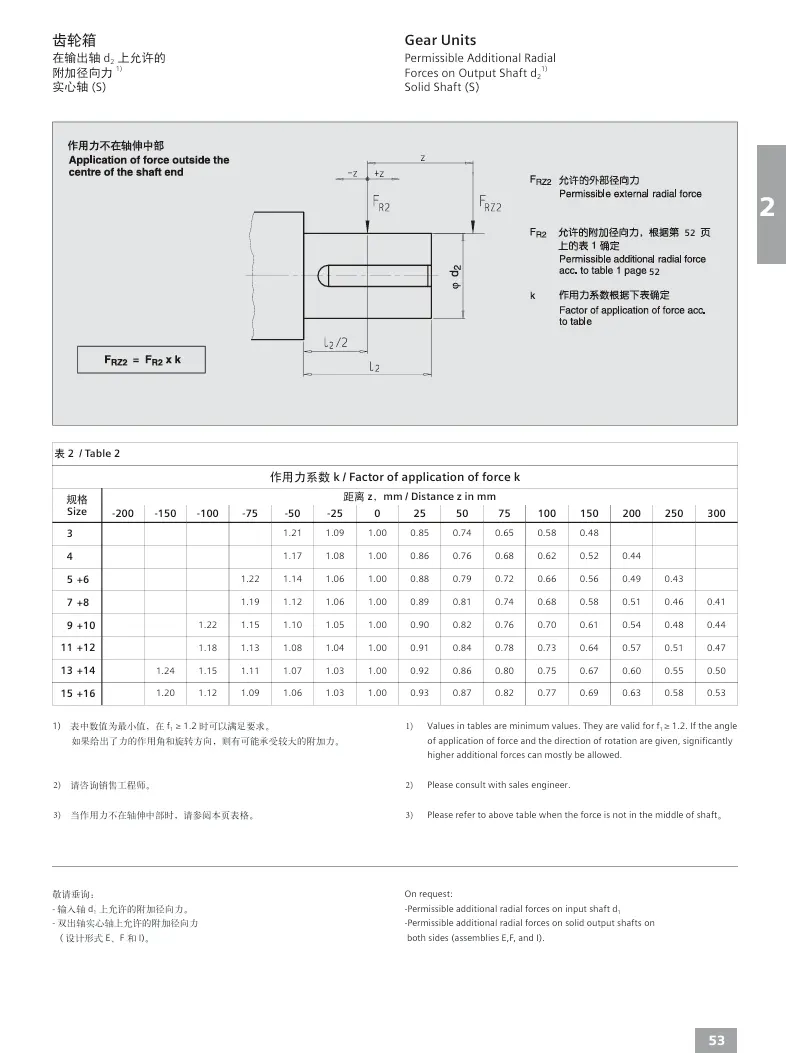

The H series helical gear high-power reducer is a brand-new hard-tooth surface reducer with a large torque scale and a modular planning of unit structure. It can be installed horizontally or vertically.There are solid shafts, hollow shafts and shrink disc hollow shafts, which are widely used in a wide range of applications. They are carburized and quenched with high-strength and high-quality alloy steel. They have the advantages of high-efficiency and high-life gears, high allowable axial and radial loads, low operating noise, high reliability, and compact structure.

1. When the reducer is installed, special attention should be paid to the alignment of the central axis of the transmission. The error in the alignment should not exceed the compensation amount of the coupling used in the reducer.After the reducer is aligned according to the requirements, it can obtain a better transmission effect and a longer service life.

2. When installing the transmission parts on the output shaft of the reducer, you must pay attention to the softness of the operation, and it is forbidden to use tools such as hammers and rough devices.It is better to use the device fixture and the internal thread of the shaft end to install the device, and press the transmission parts into the reducer shaft with the force of the bolts, which can protect the internal parts of the reducer from damage.

3. There are many types of couplings used in the reducer, but it is better not to use steel fixed couplings. Such couplings do not have radial offset compensation and the device is more difficult. The difference between the reducer and the reducer, once the device is improper, the load will be increased, and the bearing will be damaged, the reducer planning manual, and even the output shaft will be broken.