PRODUCTS

Reduction Gear Manufacturers

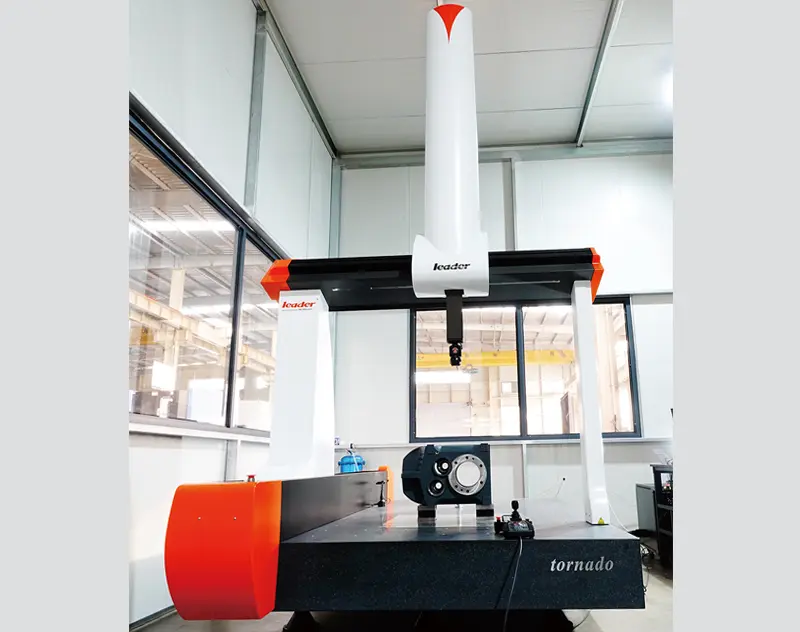

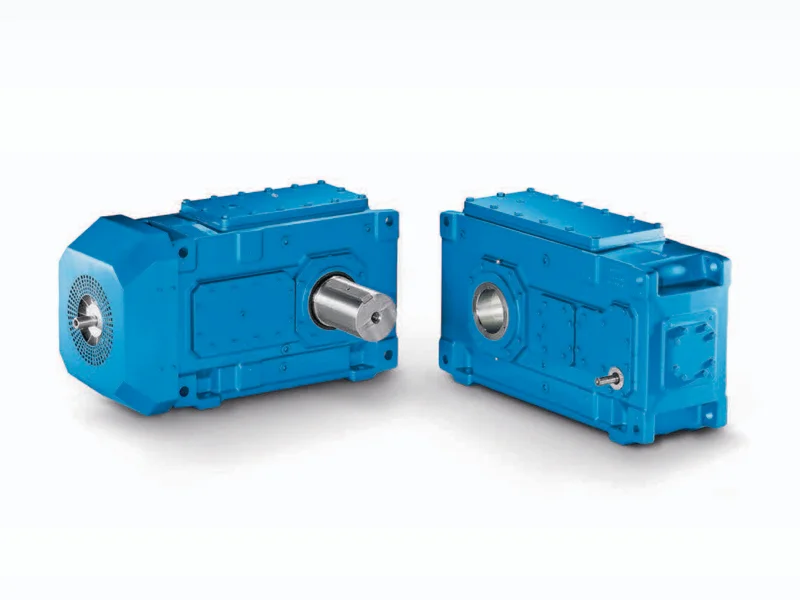

ZDY Series Hard Tooth Surface Cylindrical Gear Reducer

Keywords:

ZDY Series Hard Tooth Surface Cylindrical Gear Reducer

Subcategory:

BLG Gear Units

Product overview

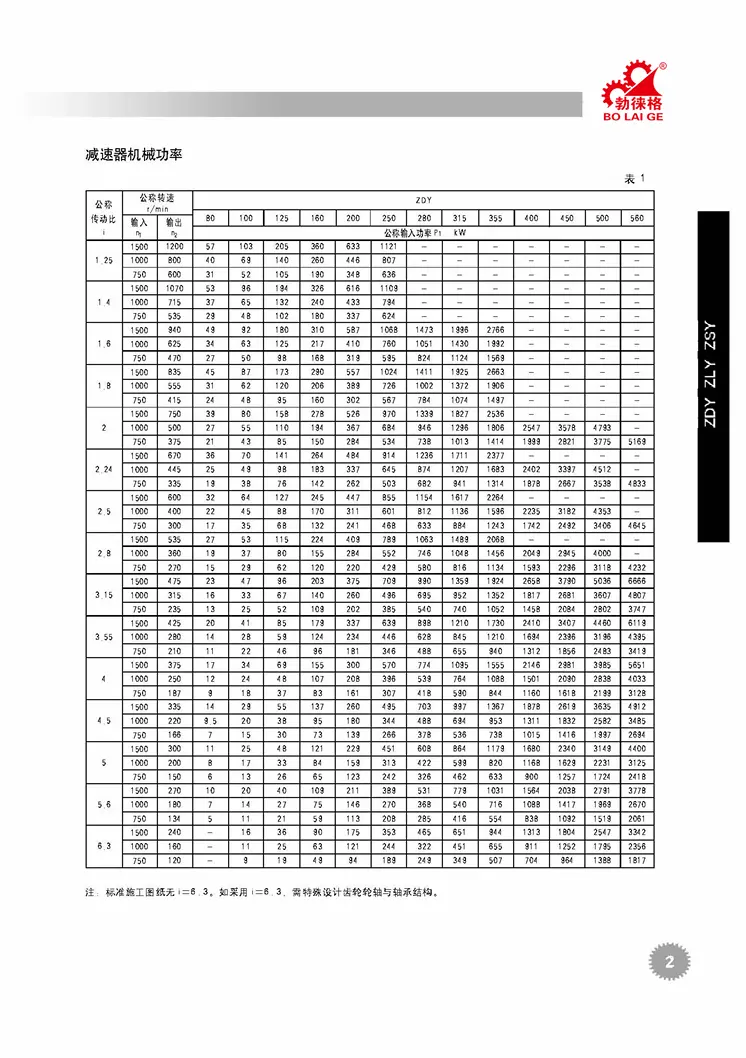

ZDY series gear reducer is a hard-toothed cylindrical gear reducer produced in accordance with the national professional standard JB/T8853. It has the advantages of small size, light weight, high carrying capacity, long life, high efficiency and low noise. It is an ideal deceleration transmission device, with the international level in the 1980s; it is widely used in metallurgy, mining, petrochemical, energy, transportation, cement, construction and light industry industries.

Conditions of use

The ambient temperature is -40~+45℃. If it is below 0℃, the lubricating oil needs to be preheated to above 0℃ before starting. The high-speed shaft speed is not greater than 1500r/min.;

The circular speed of gear transmission is not greater than 20m/s.

Product features

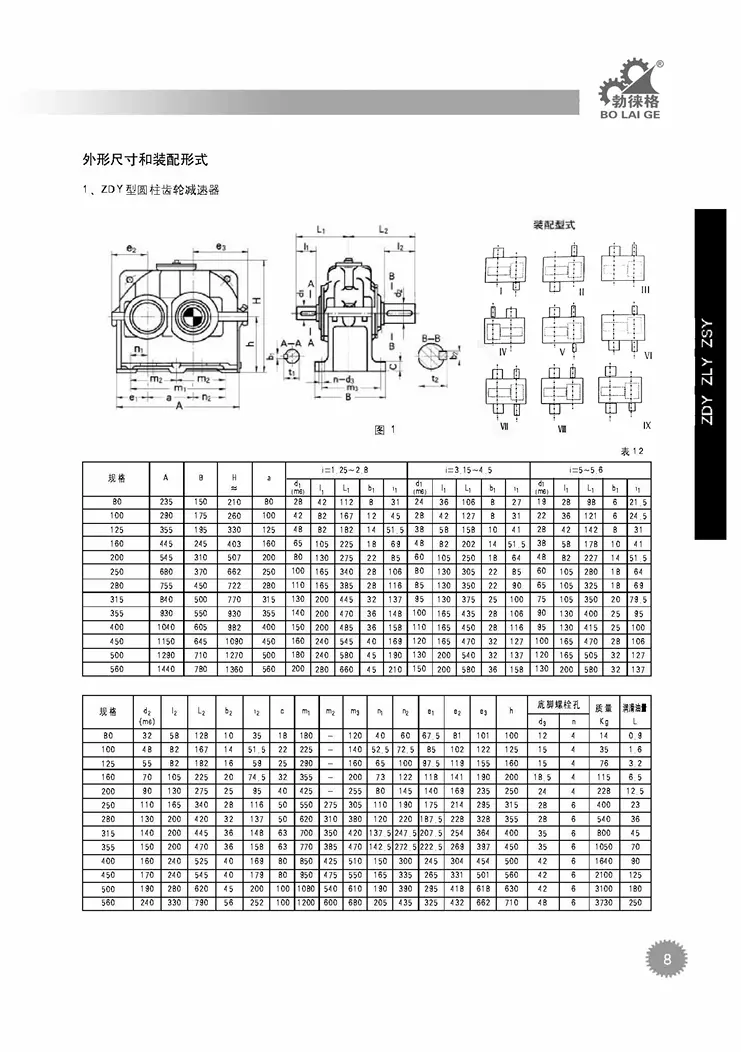

This series of reducers has been optimized for design.The gears are made of high-quality alloy steel. After forging, tooth making, and strict heat treatment, THE gears ARE ground by the Swiss REISHAUER gear grinding machine, and the accuracy can reach GB/T10095-88 standard level 5.

Wide speed ratio range: nominal speed ratio single-stage 125 to 56, two-stage 63 to 20, three-stage 224 to 100

High mechanical transmission efficiency: single stage is greater than 96:5%, two stages are greater than 93%, and three stages are greater than 90%

The reducer can be used for operation in both positive and negative directions. When the user has one-way operation and reverse braking requirements for the reducer, a backstop can be configured at the high-speed shaft end.

Smooth operation and low noise

Small size, light weight, long service life and high carrying capacity

Easy to disassemble, easy to maintain, and easy to install.

What should I provide when I choose gearbox/speed reducer?

The best way is to provide the motor drawing with parameter. Our engineer will check and recommend the most suitable gearbox model for your reference. Or you can also provide below specification as well:

1) Type, model and torque.

2) Ratio or output speed

3) Working condition and connection method

4) Quality and installed machine name

5) Input mode and input speed

6) Motor brand model or flange and motor shaft size

Are you a motor manufacturer?

Yes, we are motor manufacturer. we develop and produce both the motors and gear reducers all by our own factory.

How long does it take to finish my order?

Normally your order could be delivery in 7-15 days, some hot sales products could be fast delivered in 1 week. The specific delivery time depends on the items and the quantity of your order.

Can I get a sample first?

Sure, we are honored to offer you sample for test before placing a formal order.

How does your factory do regarding quality control?

Quality is priority. We always attach great importance to quality control from the beginning to the end of the production. Every product will be fully assembled and carefully tested before packed.

Any Other Question, Please Feel free to contact us!

MORE PRODUCTS

BLG Gear Units

-

F Series Reducer

The basic type of two-stage input and output rotation direction is the same, and the three-stage is opposite; consult separately when F/R is combined.

-

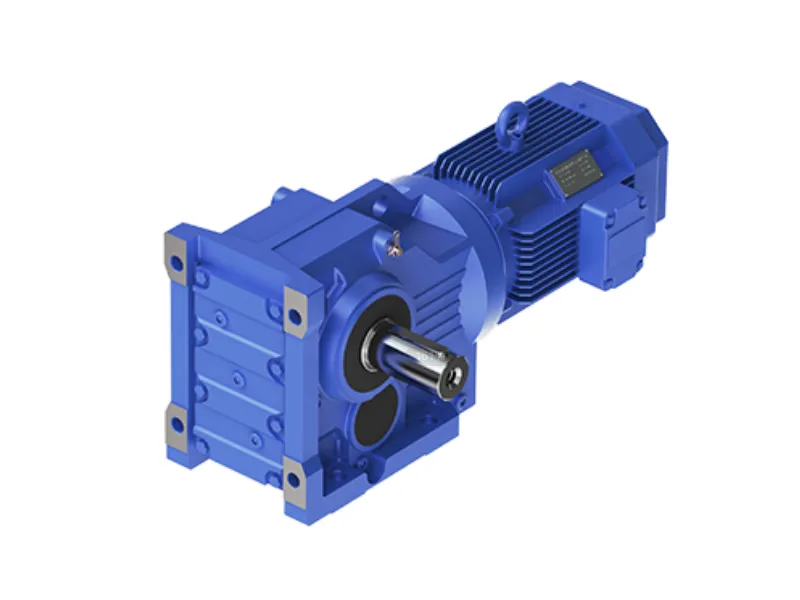

K Series Reducer

The vertical output of the four series of reducers, compact structure, high torque transmission on the hard tooth surface, and high-precision gears ensure stable work, low noise, and long life.

-

S Series Reducer

The concave and convex surface of the body has a heat dissipation effect, strong vibration absorption, low temperature rise, and low noise.

-

R Series Reducer

The R series helical gear hard tooth surface reducer is made of high-quality forged steel material, a steel cast iron box, and the gear surface is subjected to high-frequency heat treatment.

-

X/B Series Horizontal Cycloid Needle Wheel Reducer

The machine is divided into horizontal, vertical, biaxial and direct connection assembly methods, and is the preferred equipment for metallurgy, mining, construction, chemical industry, textile, light industry and other industries.

-

X.B Vertical Cycloid Needle Wheel Reducer

The machine is divided into horizontal, vertical, biaxial and direct connection assembly methods, and is the preferred equipment for metallurgy, mining, construction, chemical industry, textile, light industry and other industries.

-

WB horizontal cycloid needle wheel reducer

X/B cycloid needle wheel reducer is a kind of machinery that realizes deceleration by engaging cycloid needle teeth in accordance with the principle of planetary transmission with less tooth difference.

-

WP Worm Gear Reducer

WP worm gear reducer is developed on the basis of WD reducer. The worm gear is made of 45# high-quality steel and processed by heat treatment.

-

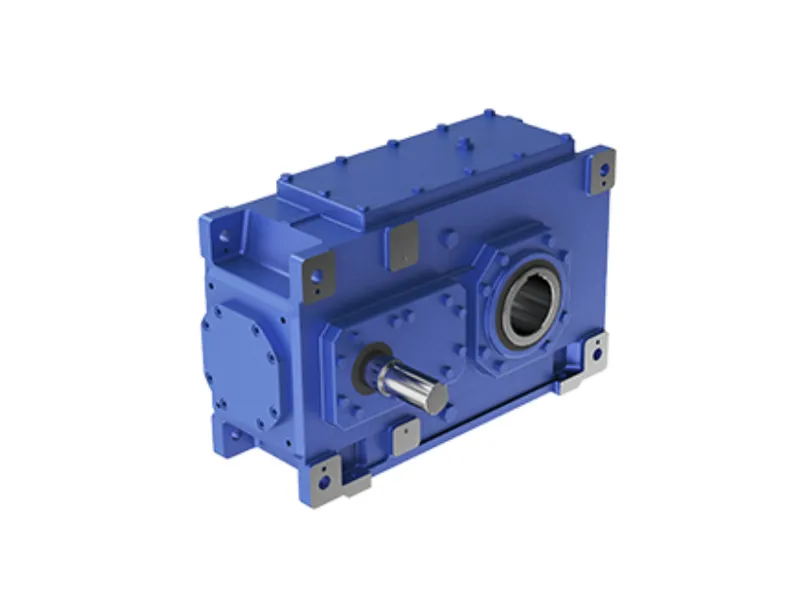

H/B Series High-power Reducer

It can be installed horizontally or vertically.There are solid shafts, hollow shafts and shrink disc hollow shafts, which are widely used in a wide range of applications.

-

H series High-power Reducer

A reducer is an independent component composed of gear transmission, worm transmission, and gear-worm transmission enclosed in a rigid housing.

-

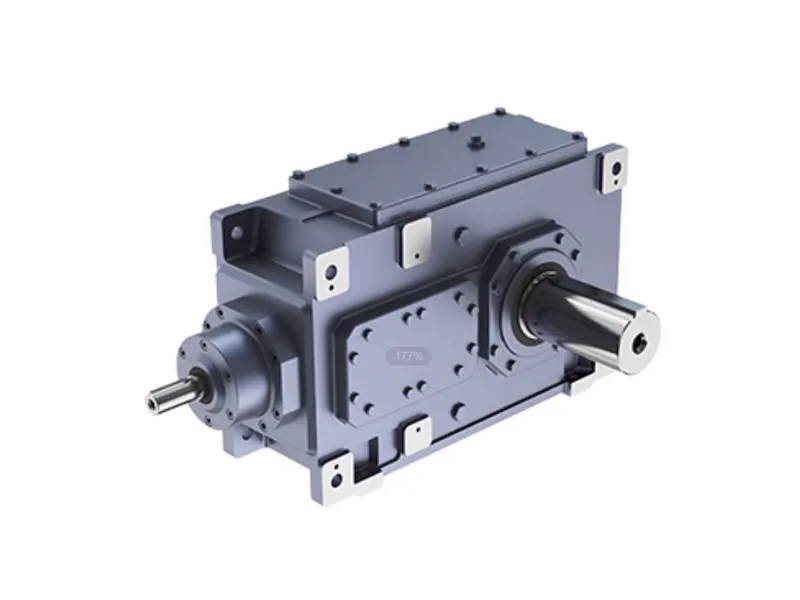

H/B high-power Combined Reducer

HB standard industrial gearboxes adopt sound-absorbing box structure, large box surface area and large fans, cylindrical gears and spiral bevel gears all adopt advanced gear grinding technology

-

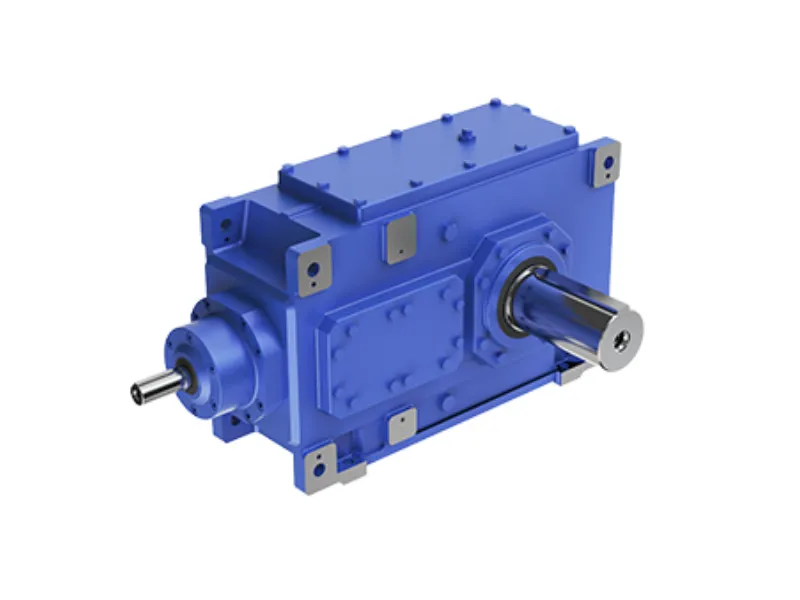

High-power Reducer

The H and B series industrial gearboxes adopt a universal design scheme to realize a universal box for parallel shafts and straight-cross shafts.

-

ZDY Series Hard Tooth Surface Cylindrical Gear Reducer

ZDY series gear reducer is a hard-toothed cylindrical gear reducer produced in accordance with the national professional standard JB/T8853.

-

T Sprial Hevel Gear Units

The T-series spiral bevel gear steering box, also known as the T-type steering box, commutator, and steering gear, is an essential transmission product in the machinery industry.

-

HB Series Gear Units

The basic gear unit can be optimally adapted to customer requirements by fitting different add-on pieces like motor bell housings,gear unit swing-bases or backstops.

Reducer series

-

F Parallel Shaft Helical Gear Units

F series parallel shaft helical gear reducer is a high-tech mechanical equipment manufactured in combination with international technical requirements, which has the characteristics of space saving

-

K Helical-bevel Gear Units

K series reducer can meet the needs of various working environments and use scenarios.In addition, the K series reducer also has a high overload capacity, a wide power range, ranging from 0.18KW to 200KW, torque range from 10N·m to 58500N·m

-

R Rigid Tooth Fank Helical Units

R series helical gear hard tooth surface reducer is a high-performance reducer with high carrying capacity, low noise, high efficiency, long life and other characteristics.

-

YCJ Series Geared Motor

High-strength materials: The box body of the gear box is cast with high-strength cast iron to ensure the stability and durability of the structure.

-

U Series Geared Motor

The design of this series of motors takes into account the characteristics of space saving, reliability and durability, and strong overload resistance.

-

S Helical-wom Gear Units

The concave and convex design of the surface of the body helps to dissipate heat and absorb vibration, maintain low temperature rise and low noise.

Worm Gear Reducer Series

-

SWL/JWM Screw Lift

SWL worm gear screw elevator is a kind of basic lifting component, which has many advantages such as compact structure, small size, light weight, wide power source, no noise

-

AS Precision Servo Worm Gear Reducer

Worm gear reducer has the characteristics of small clearance, high efficiency, large speed ratio, long life, low vibration, low noise, low temperature rise, beautiful appearance, light structure

-

WJ Worm Gear Reducer

WJ series worm gear reducer is widely used in WJ series reducer, suitable for food, cooking machinery, printing machinery, woodworking machinery, small textile machinery, rubber machinery

-

RV Shaft Input Type Worm Gear Reducer

The input methods of rv precision planetary reducer are divided into: hole input, shaft input, and extension worm shaft type; the output methods of reducer are divided into: hole output, one-way shaft output, and two-way shaft output.

-

RV Series Worm Gear Reducer

Worm gear reducer products are based on meeting the parameters of the worm gear according to the national standard GB10085-88.

-

YWJ Series Turbo Screw Lift

YWJ and WJ series worm gear screw lifts complete the functions of lifting, descending, propulsion, and flipping through worm gear transmission screws.